Tube for Peristaltic (Roller) Pump

General Information

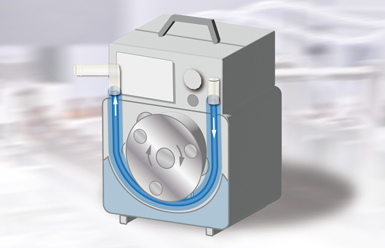

In order to deliver the fluid in a fixed quantity, the peristaltic pump has been widely used in various industries (such as analytical instruments, food industry, functional water production, ink-jet printing and polishing). Since each customer transfers different types of fluid, there are various requirements for tube. However, there is one thing in common. Due to the nature of peristaltic pump (repeated movements of "press and crush"), the tube has to have a great flexibility, duration and restoring force (often called as Compression Set).

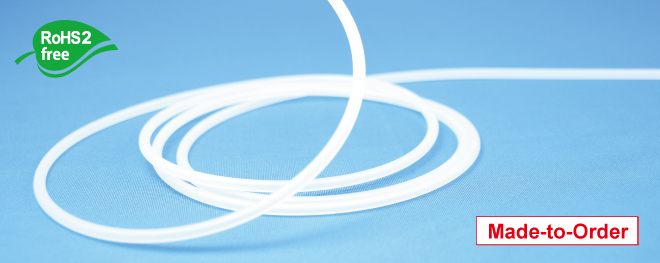

For a peristaltic pump tube, a silicone tubing has been widely adopted. However, a silicone tubing has two big disadvantages. It does not have great resistance against chemicals and oils. Also, it is relatively weak in durability (low durability). Instead, HAKKO can offer various kinds of pump tubes for these applications. (Besides, HAKKO can provide the technical data such as when the grease is applied to the tube.)

For chemical resistance data on frequently used fluids for peristaltic pump applications, please refer to the table below.

Chemical Resistance Data

| Base | Chemical Name | Olefin Elastomer | Styrene Elastomer |

| Acid | Hydrochloric Acid (35%) | $\bigcirc$ | $\times$ |

| Hydrochloric Acid (98%) | $\bigcirc$ | $\times$ | |

| Nitric Acid | $\bigcirc$ | $\times$ | |

| Alkali | Caustic Soda (20%) | $\bigcirc$ | $\bigcirc$ |

| Sodium Hypochlorite | $\bigcirc$ | $\bigcirc$ | |

| Inorganic Chemical | Bromine | $\times$ | - |

| Water | $\bigcirc$ | $\bigcirc$ | |

| Ether/Ketone | Acetone | $\triangle$ | $\times$ |

| Methyl Ethyl Ketone (MEK) | $\triangle$ | $\times$ | |

| Diethyl Ether | - | $\times$ | |

| Tetrahydrofuran | $\times$ | $\times$ | |

| Alcohol | Methyl Alcohol | $\bigcirc$ | $\bigcirc$ |

| Ethyl Alcohol | $\bigcirc$ | $\bigcirc$ | |

| Isopropyl Alcohol | $\bigcirc$ | $\bigcirc$ | |

| Oil | Kerosene | $\times$ | $\times$ |

| ASTM No.3 | $\times$ | - | |

| Gasoline | - | $\times$ | |

| Ink-Related Solvents | Acrylic Acid Ester | $\triangle$ | - |

| Glycerol | $\bigcirc$ | - | |

| Diethylene Glycol | $\bigcirc$ | - | |

| Ethylene Glycol | $\bigcirc$ | - | |

| Diethylene Glycol Diethyl Ether | $\triangle$ | - | |

| Aromatic | Toluene | $\times$ | $\triangle$ |

| Xylene | $\times$ | $\triangle$ | |

| Aliphatic | N-Hexane | $\times$ | $\times$ |

| Cyclohexane | $\times$ | $\times$ | |

| Carboxylic Acid | Acetic Acid (10%) | $\bigcirc$ | $\times$ |

| Ethyl Acetate | $\triangle$ | $\times$ |

$\bigcirc$: Can be used without any influence, or almost no influence on material.

$\triangle$: Can be used though having an influence on material to some extent.

Additional check before in use is required.

$\times$: Cannot be used.

- : No Data

*If you are interested in this Made-to-Order Offer (various hardness from Shore A 55 to Shore A 75, size and color), please fill out the following form and contact us.