Before using HAKKO EIGHTRON products, please make sure to read following instructions in order to use HAKKO EIGHTRON products safely.

HAKKO is not liable for personal injury or property damages if you do not follow the cautionary instructions below. We strongly urge you to follow these instructions.

1. Cautions in Use: General Cautions

- Please comply with the use conditions mentioned in our catalog such as working pressure, temperature, and minimum bend radius.

- Since hoses contract or extend due to the inner pressure, hoses should be installed with adequate space.

- When pressure is applied, operate the valve slowly in order not to develop impact pressure, which might cause the rupture of the hose.

- Hoses should not be used below the minimum bend radius. If you use the hoses below the minimum bend radius, hoses may be folded or the pressure resistance might go down.

- Please do not bend extremely near the fittings. This leads to the damage of the hose.

- Please do not apply unreasonable force such as kinking and pulling to the hoses. This results in the bursting of the hose or coming off from the fittings.

- Please do not pull or drag the hoses. This damages the surface of the hose, leading to having a hole onto the hose and bursting.

- Please do not bring the hoses close to fire or heat sources.

- Please do not place heavy weight on hoses. Hoses should not be running over by vehicles.

- Please do not make scratches on the hoses with cutters or knives.

- Hoses made of soft vinyl chloride (PVC) should not be contacted with resins (such as PS and ABS), which contains styrene, and moldings which are made of hard vinyl chloride resin. Components of soft vinyl chloride (PVC) may move to moldings, leaving marks behind and resulting in danger of deterioration.

- Hoses should be selected and used in accordance with what kind of fluids and atmospheres are flown in the hose. Also, make sure you check the chemical resistance data in our catalog before selecting particular hoses. If you have any questions or need more information, please feel free to contact us.

- For hose fittings, please use HAKKO original fittings applicable to each product. In case you end up using other manufacturers' fittings, it might lead to the fluid leakage, coming off from the fittings, and the bursting of the hose. For these reasons, we highly recommend you to use HAKKO original fittings with HAKKO hose. Unavoidably, if you use the fittings other than HAKKO original fittings, please use the joints to seal an inner surface of the hose. Please do not use the joints to seal an outer surface of the hose. Any problems occurred by using other manufacturers' fittings are NOT guaranteed.

- When food grade hoses are purchased and used for the first time, make sure that hoses must be washed and cleaned. In case of transferring hot water, temperature range must be below 80 degree Celsius (176 Fahrenheit), working pressure is 0.1MPa (1 Bar) or less, and 30 minutes is the maximum acceptable limit. After cleaning up, check the conditions of the hose and fittings before using.

- Please do not use HAKKO EIGHTRON products for applications of medical or medical treatment.

- When HAKKO laminated hose is crimped with a commercially available joint, cracks might appear in the inner layer. As a result, fluid leakage might occur. If you are looking for HAKKO laminated hose with Ferrule Fitting crimping type, please contact us.

2. Cautionary Instructions for Each Product

2-1. PRESSURE HOSE [E-TB] & Oil-Proof PRESSURE HOSE [E-STB]

- E-TB and E-STB are not food grade hoses. Please do not use E-TB and E-STB for transferring food and beverage.

- E-TB and E-STB are designed for positive pressure. Please do not use E-TB and E-STB for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-TB and E-STB is downloadable: E-TB: "Precautions for Use" and E-STB: "Precautions for Use."

2-2. Spring Hose [E-SP]

- E-SP is not a food grade hose. Please do not use E-SP for transferring food and beverage.

- When you cut the spring wire, be careful not to get hurt on your hands, because the spring wire may stick out at the cross-section of the hose. When the spring wire sticks out, cut it off neatly with a nipper. For visual image of how to cut, please refer to this.

- E-SP (All sizes from I.D. 10mm to I.D. 50mm for a new E-SP - Marking Color is Black) stands proof against negative pressure (can be used in vacuum conditions). [For an old E-SP - Marking Color is White, please do not use E-SP-10 and E-SP-12 for negative pressure.]

- E-SP does not eliminate the electricity which has already been charged to the fluid. Please make sure to take another approach to eliminate the electricity which has already been charged to the fluids. If the high-insulated fluids, which are likely to give out static electricity, high-flammable fluids, which are flown inside the hose, or "Spring Guards" are used under environments where there are high flammable things around, please make sure you take out the build-in spring wires to eliminate static electricity. In case "Spring Guards" are not grounded, the Steel Wire will become suspended conductors to accumulate and discharge static electricity, resulting in danger of causing fire.

- The information on "Precautions for Use" for E-SP is downloadable: E-SP: "Precautions for Use."

2-3. SUNFOODS HOSE [E-SF]

- Although E-SF conforms to the Food Sanitation Law (No.370 of the Ministry of Health and Welfare for Food Sanitation), water containing chlorine may give out the odor. Depending on the conditions of water quality and temperature, the odor of the hose may transfer to the fluids, affecting the taste.

- E-SF is designed for positive pressure. Please do not use E-SF for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-SF is downloadable: E-SF: "Precautions for Use."

2-4. KY SUNFOODS HOSE [E-KYS]

- For E-KYS, be careful that working pressure and temperature range of E-KYS equipped with EIGHTLOCK Fittings are not the same as those of E-KYS without EIGHTLOCK Fittings.

- The inner layer of E-KYS is made of olefinic resin. Thus, if E-KYS is used under high temperature with attaching to copper alloy or chlorine-related fluids are flown, the inner layer might degrade.

- Depending on the kinds of fluids, temperature, and detention time, the odor of the hose might transfer to the fluid.

- E-KYS is a laminated structure hose. Even though the inner layer of the hose is resistance to fluids, depending on working environments, the fluids would be permeating through the inner layer, resulting in the danger of swelling and degradation of the middle layer or outer layer.

- E-KYS is made of olefinic resin and styrene resin. Please do not use E-KYS for transferring lubricant oil and solvents.

- E-KYS is designed for positive pressure. Please do not use E-KYS for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-KYS is downloadable: E-KYS: "Precautions for Use."

2-5. KY TUBE [E-KYT], KY COIL Hose [E-KYC], and KY SOFT BRAID Hose [E-OHB]

- Please do not contact with products made of soft vinyl chloride (PVC). This might transfer the PVC plasticizer to those hoses.

- For E-KYC, be careful that working pressure and temperature range of E-KYC equipped with EIGHTLOCK Fittings are not the same as those of E-KYC without EIGHTLOCK Fittings.

- The inner layer of E-KYT, E-KYC, and E-OHB is made of olefinic resin. Thus, if those are used under high temperature with attaching to copper alloy or chlorine-related fluids are flown, the inner layer might degrade.

- Depending on the kinds of fluids, temperature, and detention time, the odor of the hose might transfer to the fluid.

- E-KYT, E-KYC, and E-OHB are laminated structure hoses. Even though the inner layer of the hose is resistance to fluids, depending on working environments, the fluids would be permeating through the inner layer, resulting in the danger of swelling and degradation of the middle layer or outer layer.

- E-KYT, E-KYC, and E-OHB are made of olefinic resin and styrene resin. Please do not use them for transferring lubricant oil and solvents.

- E-KYT and E-OHB are designed for positive pressure. Please do not use them for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-KYT, E-KYC, and E-OHB is downloadable: E-KYT: "Precautions for Use", E-KYC: "Precautions for Use", and E-OHB: "Precautions for Use."

2-6. Flexible Fluorine (ETFE) Resin Hose Series [E-SJSP & E-SJSPUS]

- E-SJSP & E-SJSPUS do not eliminate the electricity which has already been charged to the fluid. Please make sure to take another approach to eliminate the electricity which has already been charged to the fluids. If the high-insulated fluids, which are likely to give out static electricity, high-flammable fluids, which are flown inside the hose, or "Spring Guards" are used under environments where there are high flammable things around, please make sure you take out the build-in spring wires to eliminate static electricity. In case "Spring Guards" are not grounded, the Steel Wire will become suspended conductors to accumulate and discharge static electricity, resulting in danger of causing fire.

- The inner layer of E-SJSP & E-SJSPUS are made of ETFE. Thus, E-SJSP & E-SJSPUS show higher levels of chemical resistance. However, depending on the kinds of chemicals, concentrations, and temperature, E-SJSP & E-SJSPUS might swell or deteriorate. Please check the chemical resistance data listed on HAKKO website or general catalog.

- Depending on the kinds of fluids, temperature, and detention time, the odor of the hose might transfer to the fluid.

- This is a multi-layer hose. In terms of chemical resistance, the outer layer is inferior to the inner layer, so please do not soak E-SJSP & E-SJSPUS into chemicals and contact with chemicals for a long time. Also, depending on working environments, the fluids would be permeated through the inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

- The information on "Precautions for Use" for E-SJSP and E-SJSPUS is downloadable: E-SJSP: "Precautions for Use" and E-SJSPUS: "Precautions for Use."

2-7. Solvent Transfer Hose [E-SV] and Paint Flex-Fluorine Hose (Ground Wire Type) [E-PFFG]

- E-SV and E-PFFG do not eliminate the electricity which has already charged to the fluid. Please make sure to take another approach to eliminate the electricity which has already been charged to the fluid. Please make sure to ground the conductive line with our original fittings. If this is not grounded, the conductive line layer and ground wire will become suspended conductors to accumulate and discharge static electricity, resulting in danger of causing fire.

- The inner layer of E-SV is made of polyamide (nylon) resin, while that of E-PFFG is made of ETFE Fluorine. Depending on the kinds of chemicals, concentration, and temperature, E-SV/E-PFFG might swell, melt, or harden. Please make sure to check the chemical resistance data available on HAKKO website or general catalog.

- Since the outer layer of E-SV and E-PFFG is not resistant to solvents, please do not infuse solvents to E-SV and E-PFFG. Even though the inner layer of E-SV and E-PFFG is resistant to fluids, depending on working environments, the fluids would be permeated through the inner layer, resulting in the danger of swelling and degradation of the middle and outer layer, and conductive line.

- Before installation, please make sure to check the value of electrical resistivity between one fitting and the other fitting. The value should be less than 1M$\Omega$.

- E-SV and E-PFFG is designed for positive pressure. Please do not use E-SV and E-PFFG for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-SV and E-PFFG is downloadable: E-SV: "Precautions for Use" and E-PFFG: "Precautions for Use."

2-8. Paint Flex-Nylon Hose [E-PFN] & Paint Flex-Fluorine Hose [E-PFF]

- Depending on the kinds of paints, E-PFN and E-PFF might swell, melt, and harden. Please make sure to check in advance and decide whether or not you can use E-PFN and E-PFF in your applications.

- The inner layer of E-PFN is made of polyamide (nylon) resin, and that of E-PFF is made of ETFE fluorine resin. Depending on the kinds of paints and using temperature, E-PFN and E-PFF might swell, melt, or harden. Please make sure to check the chemical resistance data available on HAKKO website or general catalog.

- Since the outer layer of E-PFN and E-PFF is not resistant to solvents, please do not infuse solvents to E-PFN and E-PFF. Even though the inner layer of E-PFN and E-PFF is resistant to fluids, depending on working environments, the fluids would be permeated though the inner layer, resulting in the danger of swelling and degradation of the middle and outer layer.

- E-PFN and E-PFF are designed for positive pressure. Please do not use E-PFN and E-PFF for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-PFN and E-PFF is downloadable: E-PFN: "Precautions for Use" and E-PFF: "Precautions for Use."

2-9. Air Flex-Conductive Hose [E-AFC] and NEW FLEX Air Hose [E-NF]

- E-AFC and E-NF are designed for transferring air.

- If paints, solvents, oil, and other chemicals are attached to the hose, please wipe off immediately. This is because the material of E-AFC and E-NF is polyurethane, which does not have resistance against chemicals. If you do not, the hose might swell, harden, deteriorate, and dissolve.

- E-AFC and E-NF are designed for positive pressure. Please do not use them for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-AFC and E-NF is downloadable: E-AFC: "Precautions for Use" and E-NF: "Precautions for Use."

2-10. Soft NEW FLEX Air Hose [E-SNF]

- E-SNF is designed for transferring air.

- If paints, solvents, oil, and other chemicals are attached to the hose, please wipe off immediately. If you do not, the hose might swell, harden, deteriorate, and dissolve.

- E-SNF is designed for positive pressure. Please do not use E-SNF for negative pressure (in vacuum conditions).

- E-SNF is a very soft PU air hose. Thus, we strongly recommend you to choose HAKKO original fittings [E-RSS and E-RSP], and do not use nut type fittings without spring guards.

- The information on "Precautions for Use" for E-SNF is downloadable: E-SNF: "Precautions for Use."

2-11. Air Hose (Ground Wire Type) [E-AHG]

- E-AHG is designed for transferring air.

- If paints, solvents, oil, and other chemicals are attached to the hose, please wipe off immediately. If you do not, the hose might swell, harden, deteriorate, and dissolve.

- E-AHG is designed for positive pressure. Please do not use E-AHG for negative pressure (in vacuum conditions).

- Before the installation, please measure the end-to-end resistance value among the fittings. The value should be within a range of 1M$\Omega$ or less.

- Please make sure to ground a hose. If not, the conductive line and the ground wire will become suspended conductors to accumulate and discharge static electricity, resulting in danger of causing fire.

- The conductive line and the ground wire will eliminate the static electricity, charged to the spray gun. E-AHG does not eliminate the electricity, which has already been charged to the fluid.

Please make sure to take another approach to eliminate the electricity, which has already been charged to the fluid. - The information on "Precautions for Use" for E-AHG is downloadable: E-AHG: "Precautions for Use."

2-12. Protective Spring Guards [E-HSL]

- If the high-insulated fluids, which are likely to give out static electricity, high flammable fluids, which are flown inside the hose, or "Spring Guards" are used under environments where there are high flammable things around, please make sure you take out the build-in spring wires to eliminate static electricity. In case "Spring Guards" are not grounded, the Stainless Steel will become suspended conductors to accumulate and discharge static electricity, resulting in danger of causing fire.

- The information on "Precautions for Use" for E-HSL is downloadable: E-HSL: "Precautions for Use."

2-13. Flexible Fluorine (ETFE) Resin Hose Series [E-SJ & E-SJ-CBU & E-SJECO & E-SJAST & E-SJB & E-SJBUS & E-SJV & E-SJ-BK & E-SJUS & E-SJUS-BK]

- Inner layers of laminated hoses are resistant to fluids, but depending on working environments, the fluids would be permeated through inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

- Since the outer layer of Flexible Fluorine Resin Hose Series is not resistant to solvents, please do not infuse solvents to the outer layer of those hoses.

- The inner layer of Flexible Fluorine (ETFE) Resin Hose Series is made of ETFE fluorine. Thus, this Hose Series show higher levels of chemical resistance. However, depending on the kinds of chemicals. concentration, and temperature, this Hose Series might swell or deteriorate. Please check the chemical resistance data available on HAKKO website or general catalog.

- Depending on the kinds of fluids, temperature, and detention time, the odor of this Hose Series might transfer to the fluid.

- Flexible Fluorine (ETFE) Resin Hose Series [E-SJ & E-SJ-CBU & E-SJECO & E-SJAST & E-SJB & E-SJBUS & E-SJV & E-SJ-BK & E-SJUS & E-SJUS-BK] are designed for positive pressure. Please do not use these products for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-SJ, E-SJ-CBU, E-SJECO, E-SJAST, E-SJB, E-SJBUS, E-SJV, E-SJ-BK, E-SJUS and E-SJUS-BK is downloadable: E-SJ: "Precautions for Use," E-SJ-CBU: "Precautions for Use," E-SJECO: "Precautions for Use," E-SJAST: "Precautions for Use," E-SJB: "Precautions for Use," E-SJBUS: "Precautions for Use," E-SJV: "Precautions for Use," E-SJ-BK: "Precautions for Use," E-SJUS: "Precautions for Use," and E-SJUS-BK: "Precautions for Use."

2-14. Flexible Fluorine (PVDF) Resin Hose Series [E-PD & E-PDB]

- Inner layers of laminated hoses are resistant to fluids, but depending on working environments, the fluids would be permeated through inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

- Since the outer layer of Flexible Fluorine Resin Hose Series is not resistant to solvents, please do not infuse solvents to the outer layer of those hoses.

- The inner layer of Flexible Fluorine (PVDF) Resin Hose Series is made of PVDF fluorine. Thus, this Hose Series show higher levels of chemical resistance. However, depending on the kinds of chemicals. concentration, and temperature, this Hose Series might swell or deteriorate. Please check the chemical resistance data available on HAKKO website or general catalog. (Please note that in terms of chemical resistance. ETFE is better than PVDF. Thus, if you transfer acetone or solvents, we recommend you to choose products under the category of Flexible Fluorine (ETFE) Resin Hose Series.)

- Depending on the kinds of fluids, temperature, and detention time, the odor of this Hose Series might transfer to the fluid.

- Flexible Fluorine (PVDF) Resin Hose Series [E-PD & E-PDB] are designed for positive pressure. Please do not use these products for negative pressure (in vacuum conditions).

- The information on "Precautions for Use" for E-PD and E-PDB is downloadable: E-PD: "Precautions for Use" and E-PDB: "Precautions for Use."

2-15. Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type) [E-SJD & E-SJSD]

- E-SJD and E-SJSD are developed for industrial use. In case you plan to adopt E-SJD and E-SJSD for transferring food, beverage, and other applications required safety, make sure to evaluate by yourself in advance. HAKKO CORPORATION does not guarantee the applicability and safety of these usages. HAKKO CORPORATION does not owe any responsibilities on these applications if problems occur. Do not use E-SJD and E-SJSD for any applications related to body implant, injection, and remaining some parts of E-SJD and E-SJSD into the body.

- In case E-SJD and E-SJSD are used for transferring powder, depending on the conditions, abrasion by the powder might shave the inner layer, resulting in the situation that carbon might mix into the fluid.

- In case E-SJD and E-SJSD are used for transferring food, please clean inside the hose.

- After installing with our original metal fittings, E-SJD and E-SJSD should be grounded. Also, please do not install ordinary hoses (insulators) before or after E-SJD and E-SJSD. If you use hoses without grounding or connect with insulators, E-SJD and E-SJSD will be suspended conductors to accumulate and discharge static electricity, resulting in danger of causing fire.

- E-SJD and E-SJSD do not eliminate the electricity which has already been charged to the fluid. Please take another approach to eliminate the static electricity which has already been charged to the fluid. We are not responsible for any injury or property damages even if any accidents occur outside the installation of E-SJD and E-SJSD.

- E-SJD and E-SJSD do not necessarily guarantee the prevention of disaster. Please make sure the following factors: flammability, explosiveness, the velocity limit of low dissipative material, and the decline of spraying concentration.

- The maximum length of conforming to the IEC dissipative standard (1K$\Omega$ $\leqq$ R<1M$\Omega$) is 20m. Thus, please make sure to ground E-SJD and E-SJSD within 20m (including our original fittings between one hose end and the other hose end.) If you use more than two fittings within 20m or if you use more than 1 hose over 20m, please ground the hose with each fitting or take a risk assessment approach by measuring the resistance value.

* IEC/TS 60079-32-1: 2013 7.7.3 Hose and Assembly of Hose Table: 15

- E-SJD and E-SJSD are not used for applications of medical or medical treatments.

- Please do not energize E-SJD and E-SJSD. This might lead to the burst or electric shock.

- The inner layer of E-SJD and E-SJSD contains carbon. Depending on the using conditions (such as the kind of fluids, working temperature, bending, pressurization stress, and friction, carbon might come out. When you require the pureness of the fluid, make sure to check by yourself.

- Please use our HAKKO original fittings for E-SJD and E-SJSD: E-SJD: "Fittings for Multi-Layer Tubing (with Tubing Guide)" [E-FTS-GN] and E-SJSD: "EIGHTLOCK S Fittings (with Hose Guide)" [E-ELS-GN] or "EIGHTLOCK Ferrule Fittings (with Hose Guide)" [E-ELF-GN].

- Unavoidably, if you use the joints other than HAKKO original fittings, please use the joints seal an inner surface of the hose with dissipative materials, Please do not use the joints to seal an outer surface of the hose. Please do not use plastic fittings (except conductive plastic fittings).

- Before you use E-SJD and E-SJSD, please check the resistance value between one hose end and the other hose end on a regular basis. In case the resistance value increases, stop using the hose immediately and replace into a new one.

- Since the material of the inner layer of E-SJD and E-SJSD contains carbon, it is inferior in repeated bending stress resistance as compared with E-SJ and E-SJSP. Thus, in applications where repeated bending stress is applied, please check in advance.

- Hose clamps for E-SJD and E-SJSD must be grounded and bonded. In case hose clamps are not grounded or bonded, hose clamps will become suspended conductors, resulting in accumulation of static electricity. This results in the danger of causing fire.

- The information on "Precautions for Use" for E-SJD and E-SJSD is downloadable: E-SJD: "Precautions for Use" and E-SJSD: "Precautions for Use."

2-16. Barrier Tubing (Olefin) [E-BTO]

- E-BTO is a tubing for supplying inks. Please contact us if you are using these products for other than transferring inks.

- Terms of use, operating environment, and tubing performance might be lower by applying secondary processing (such as cutting, bending, and assembling). Please evaluate this in actual settings by yourself.

- The material or the adhesive layer, barrier layer, and outer layer is inferior in chemical resistance to the inner layer. Please do not attach chemicals as they might cause swelling or cracking of the tubing when you insert fittings and you use the tubing.

- If the tubing is inserted into a joint whose nipple dimension is extremely thicker than the tubing inner diameter, it will cause whitening and cracking around the insertion area due to stress.

- Please do not use fittings with scratches or rust on the surface of the nipple when using metal fittings. This will damage the inner surface of the tubing, which might cause the tubing to rupture or leak.

- In case you use resin fittings, please do not use fittings with scratches on the surface of nipple. This will damage the inner surface of the tubing, which may cause the tube to rupture or leak. Fluid might leak depending on the conditions of the joint (parting line) of the resin joint. Check fittings before you use.

- E-BTO is designed for positive pressure. Please do not use them for negative pressure (in vacuum conditions).

- Keep a storage temperature within the range of -30 degree Celsius (-22 Fahrenheit) to 70 degree Celsius (158 Fahrenheit) in the indoor environment.

- An inner layer of E-BTO is made of polyethylene. Thus, if your inks belong to solvent-based, aggressive inks, we recommend you to choose Barrier Tubing (Fluorine) [E-BTF & E-BTF-BK].

- The information on "Precautions for Use" for E-BTO is downloadable: E-BTO: "Precautions for Use."

2-17. Barrier Tubing (Fluorine) [E-BTF & E-BTF-BK]

- E-BTF and E-BTF-BK are a tubing for supplying inks. Please contact us if you are using these products for other than transferring inks.

- Terms of use, operating environment, and tubing performance might be lower by applying secondary processing (such as cutting, bending, and assembling). Please evaluate this in actual settings by yourself.

- The material or the adhesive layer, barrier layer, and outer layer is inferior in chemical resistance to the inner layer. Please do not attach chemicals as they might cause swelling or cracking of the tubing when you insert fittings and you use the tubing.

- If the tubing is inserted into a joint whose nipple dimension is extremely thicker than the tubing inner diameter, it will cause whitening and cracking around the insertion area due to stress.

- Please do not use fittings with scratches or rust on the surface of the nipple when using metal fittings. This will damage the inner surface of the tubing, which might cause the tubing to rupture or leak.

- In case you use resin fittings, please do not use fittings with scratches on the surface of nipple. This will damage the inner surface of the tubing, which may cause the tube to rupture or leak. Fluid might leak depending on the conditions of the joint (parting line) of the resin joint. Check fittings before you use.

- E-BTF and E-BTF-BK are designed for positive pressure. Please do not use them for negative pressure (in vacuum conditions).

- Keep a storage temperature within the range of -30 degree Celsius (-22 Fahrenheit) to 70 degree Celsius (158 Fahrenheit) in the indoor environment.

- The information on "Precautions for Use" for E-BTF and E-BTF-BK is downloadable: E-BTF: "Precautions for Use" and E-BTF-BK: "Precautions for Use."

2-18. Flexible Fluorine Resin Hose Series with Ferrule Fittings (Swage Type) [E-PDB-F & E-SJB-F & E-SJSP-F]

- Followings are explanations for how to safely use fluorine resin hose series with ferrule fittings. However, some restrictions might apply. Please follow the instructions below. In case you violate the safety instructions, it hurts yourself and damages your properties. If you do not handle the flexible fluorine resin hose series with ferrule fittings (swage type) properly, you may die or get severely injured.

- Please do not put pressure on the outer layer. Hoses are mainly designed to stand proof against the inner layer. If you put too much pressure on the outer layer, collapsing or detaching the inner layer from the outer layer might happen. Thus, the lifetime of the hoses will be much shorter.

- Please do not turn on electricity. Hoses might burst or you get electrified.

- Please do not put too much vibration to the hose. If you put too much vibration on it, the ferrule fittings of the flexible fluorine resin hose series might lead to fatigue crack, which also results in leaking and bursting.

- In order not to add tension, hoses should be installed, keeping enough space. Adding positive or negative pressure to the fittings of the flexible fluorine resin hose series leads to the change in the length. Thus, without enough length, the tension might arise. The bursting of the hose may happen or the fittings come off from the hose.

- Please do not install or use the twisted hose. In case the hoses are twisted, the inner structure of the hose may change, leading to the bursting.

- The information on "Precautions for Use" for Flexible Fluorine Resin Hose Series with Ferrule Fittings (Swage Type) is downloadable: E-PDB-F, E-SJB-F, and E-SJSP-F: "Precautions for Use."

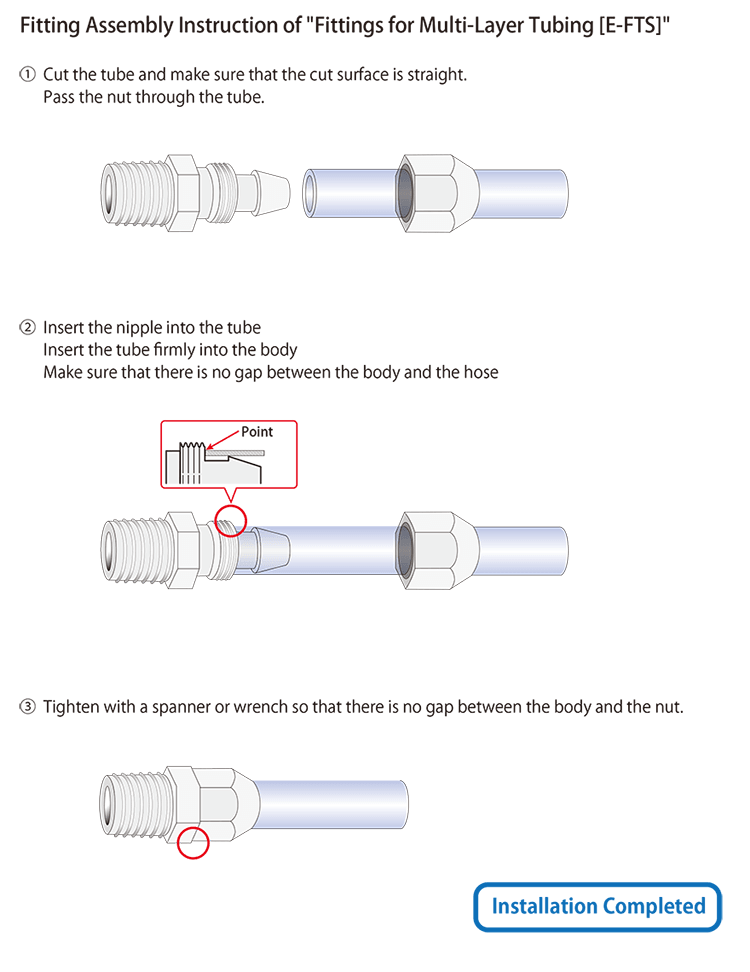

3. Cautionary Instructions on How to Cut Tube/Hose and Assemble with Fittings

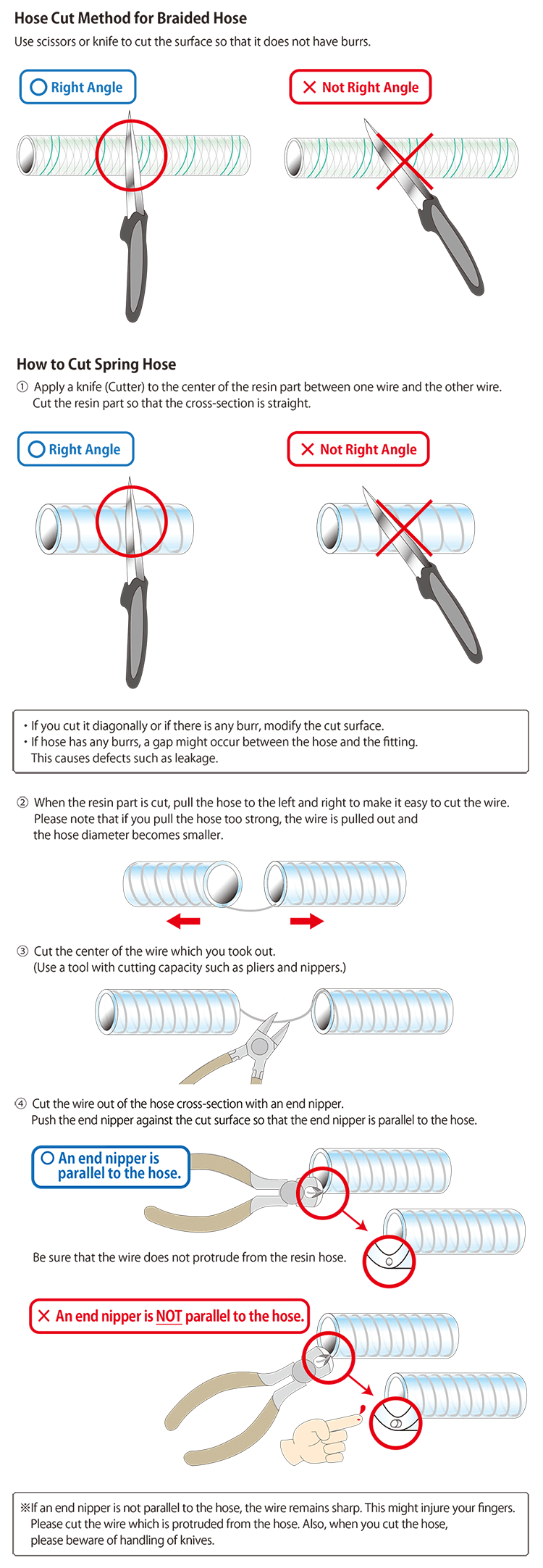

- In cutting the hose, the cross-section of the hose must be perpendicular.

[Hose Cut]

General Cautions of Hose Cut and Fitting Assembly

- When the nipple of the fitting is inserted into the hose, do not apply oil on the hose and nipple or do not warm them with fire. It may cause the hose to come off or change its shape.

- Insert the nipple of the fitting into the end of the hose until it seals against the thread base. If the nipple is not inserted adequately, the hose may come off.

- Please do not use the fittings which have scratches or rust on the surface of the nipple. Inner surfaces of the hose may be damaged and it may cause the hose to rupture or leak.

- Please use our HAKKO original fittings. In case you use other manufacturers' fittings, please use the fittings which have the barbed R on the nipples.

- Please choose the hose nipples which are suitable for hose sizes.

- Please use the joints to seal an inner surface of the hose. Please do not use the joints to seal an outer surface of the hose. (Please do not use push-to-connect joints for one-touch fittings for our products.)

- Please use the flat hose clamps required for the hose specifications. Please do not use wires or do not tighten excessively with wires. It may cause the hoses to rupture or leak.

- Please tighten the hose clamps on stipulated torques.

- Hoses turn soft at a higher temperature. Install the fittings by retightening the hose clamps required for the hose specifications.

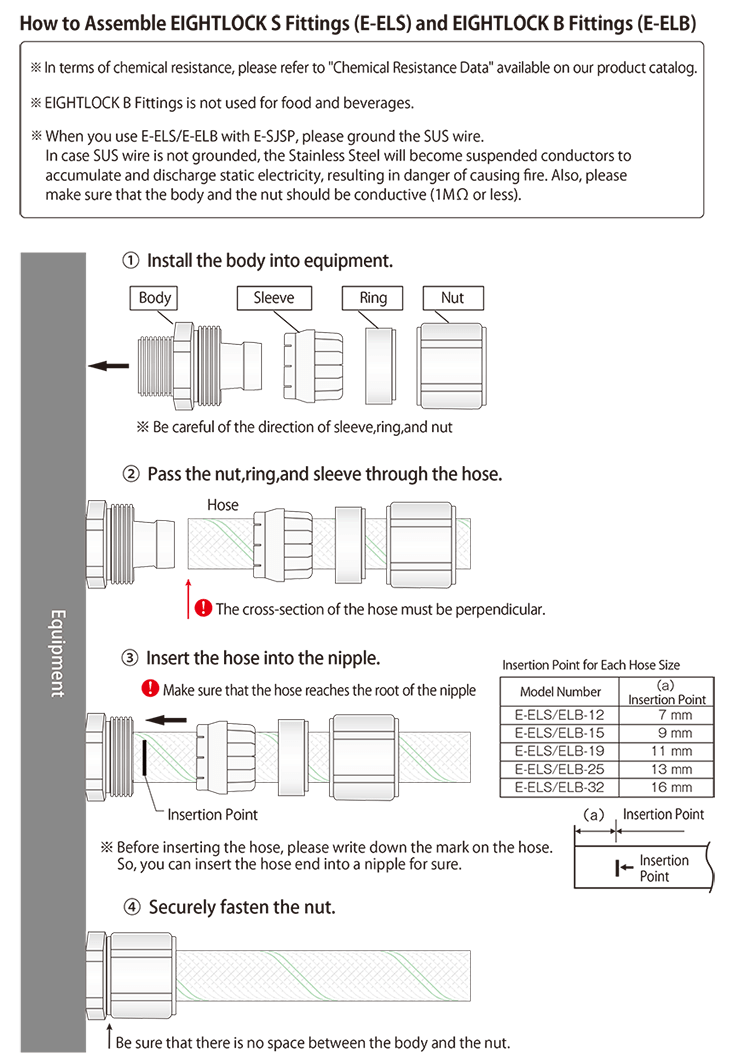

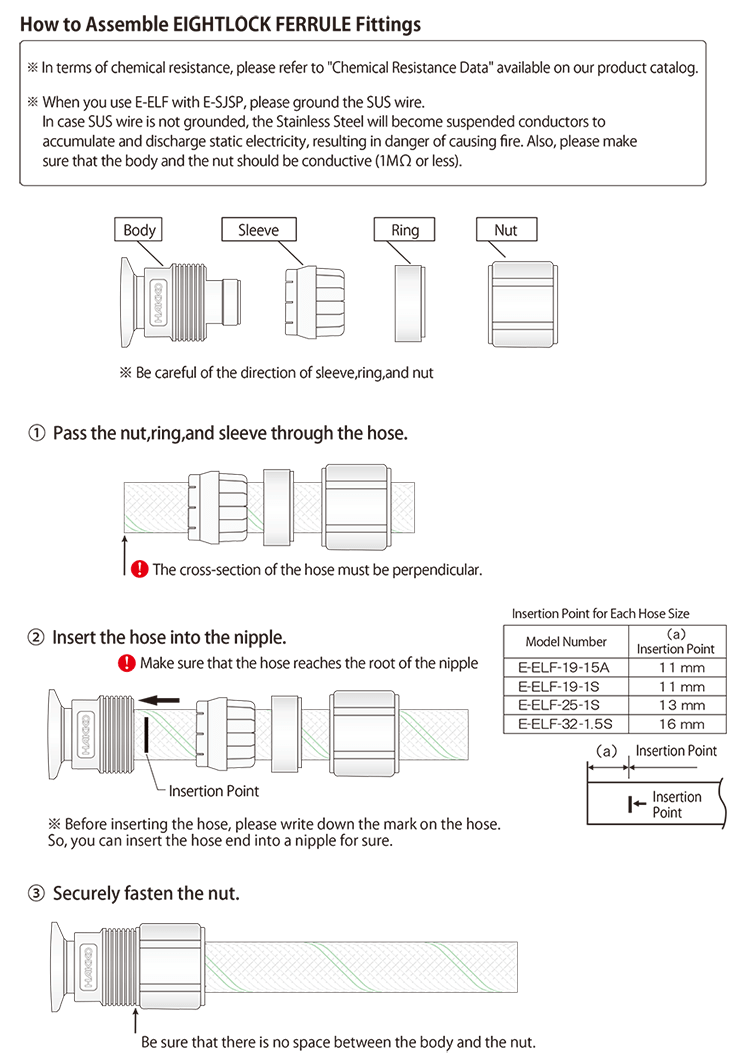

Cautions on EIGHTLOCK S/B Fittings and EIGHTLOCK Ferrule Fittings

Please use HAKKO EIGHTLOCK for the following hoses. Please do not use other hoses, which might cause leaking, coming off from the fittings and bursting.

- Flexible Fluorine (PVDF) Resin Yarn Reinforced Hose [E-PDB]

- Flexible Fluorine (ETFE) Resin Yarn Reinforced Hose [E-SJB]

- Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose [E-SJSP]

- Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose (Dissipative Type) [E-SJSD]

- Flexible Fluorine (ETFE) Resin Yarn Reinforced Hose (Ultra Soft Type) [E-SJBUS]

- Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose (Ultra Soft Type) [E-SJSPUS]

- PRESSURE HOSE [E-TB]

- Oil-Proof PRESSURE HOSE [E-STB]

- SUNFOODS HOSE [E-SF]

- KY SUNFOODS HOSE [E-KYS]

- KY COIL HOSE [E-KYC]

- When you use for the first time, please wash out our fittings carefully. (We do not sterilize fittings at all when we shipped out from our warehouse.)

- When you use for transferring food, please do not soak fittings and hoses into the fluid. Due to the leftover, this might cause the bacteria to grow. As a result, the fittings might corrode.

- When you install hose with fittings (such as installing a hose and tightening a nut), please conduct this at room temperature (20$^\circ$C $\pm$ 10$^\circ$C). When you install at low temperature, the thread portion of the fittings is likely to be galling (wearing). On the other hand, when you install at high temperature, this might lower the pressure resistance.

- When you reuse HAKKO EIGHTLOCK, please do not use a cutter or knife in taking the hose off. This might damage the nipple of the fittings. Please cut the hose shortly and take it off by a pair of pliers. Also, if you find any damages or burr on the surface of the nipple, please do not reuse the fittings. This damages the surface of the hose and leads to the bursting and leaking. Please check whether or not the body and the nut do not have any irregularities. If there are any irregularities, please stop using the fittings.

- When you install a hose, please make sure the insertion point and the directions of the ring and sleeve.

- For E-KYS and E-KYC, be careful that working pressure and temperature range of E-KYS and E-KYC equipped with EIGHTLOCK Fittings are not the same as those of E-KYS and E-KYC without EIGHTLOCK Fittings.

- When you reuse EIGHTLOCK Fittings, please use a new sleeve. Sleeve is not reusable.

- When you adopt E-SJSD with E-ELS, please fasten the nut without any space between fitting body and fitting nut. In case there is a space, nut will become suspended conductors, leading to accumulating static electricity. This results in danger of causing fire. Also, please make sure to check the conductivity (less than 1M$\Omega$) between fittings itself and nut when you install the fittings or conduct a regular inspection.

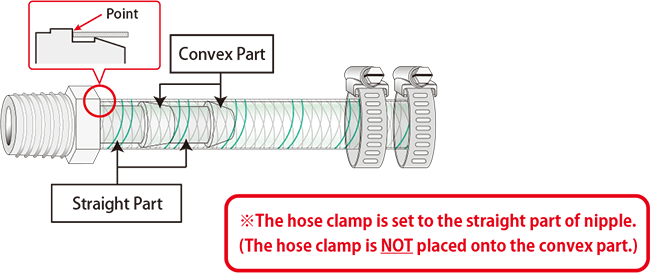

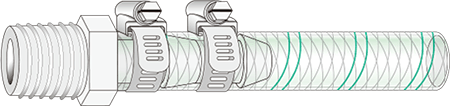

How to Assemble EIGHTNIPPLE Fittings

(A) Cut the hose in a perpendicular way. Pass two hose clamps through the hose.

(B) Insert the nipple to the hose. Make sure to insert to the end. There should be no gap between hose and fittings.

(C) Tighten the two hose clamps by torque. Hose clamp manufacturer specifies the tightening value. Please follow this value. Pressure performance of the hose might vary depending on its manufacturer and part number.

Assembly Done !

Without grounding, the hose clamps might become insulators, accumulating and discharging static electricity. This results in causing a fire to combustibles, leading to explosion.

4. Cautions in Maintenance and Inspection

- Hoses are greatly affected by use conditions and environments. In case hoses are used outdoor,

- the surface of the hoses will be damaged and the quality will deteriorate quickly, compared with ones used indoor.

- The conditions of the hoses and fittings should be inspected regularly. If something unusual things listed below occur, stop using the hoses immediately and replace them with new ones:

* Abnormal Appearance...Tear, Scratches, Swelling, Crack, Curve, Deformation, and Exposure of Reinforced Yarns due to Abrasion

* The Bursting of Inner or/and Outer Layers of the Hoses, Hardening, Dramatic Change in Color, and Leaking Fluids

5. Cautions in Storing

- Please do not directly contact with rubber products such as rubber hose and rubber board. This causes the hose to change in color, transfer the components, and swell the hoses.

- In case the hoses are stored, get rid of remaining fluids inside the hoses, clean up any dusts on the surface of the hose and avoid twisting/holding the hoses.

- Please do not store the hose under the extremely bended conditions.

- Please store the hose on the flat, smooth surfaces; otherwise, hoses may change its shape.

- Please do not expose the hose to direct sunshine, wind, or rain. Store the hose in the low humid, well-ventilated, cold, and dark places.

- Please store the hose without having foreign matters and dusts inside the hose.

- Please do not pile up the hoses in large quantity.

6. About the Numerical Value of Working Pressure

- Working pressure specified in the catalog is based on using our HAKKO original fittings and hose clamps (tightening a hose with two Tridon hose clamps).

- Depending on the specifications of the fittings, working pressure might go down.

* Tightening torques of hose clamps are maximum values recommended by the manufacturer. * In case there are no HAKKO original fittings for the hoses, the value is set by our recommended barb fittings.

7. In case of Disposing

- In case of disposing, follow the local governmental regulations.

Revised: November 24, 2024