General Questions about Hose/Tube/Fittings

Answer 1: We are afraid that we cannot set the general lifetime, since the lifetime of the hose heavily depends on using conditions and using environments.

If you find the following features, we strongly recommend that it is time to replace into a new hose.

...Tear, Scratches, swelling, crack, curve, deformation, and exposure of reinforced yarns due to abrasion. The bursting of inner layer and/or outer layers of the hoses, hardening, dramatic change in color, and leaking fluids.

Answer 2: As temperature goes up, hose/tube gets soften, leading to lower working pressure.

Each product has technical data regarding "Relationship between Working Temperature and Maximum Working Pressure." Please check this data for each product.

Answer 3: You can cut a tube with a tube-cutter. For a hose, you can cut with a knife or a hose cutter.

To cut a spring hose, make sure to cut the spring wire off neatly with a nipper.

Answer 4: In case of disposing, please follow the local governmental regulations.

Answer 5: Burst pressure is the value of pressure when hose gets burst after adding pressure to the hose. Usually, a yarn-casting off or pinhole bursting occurs when hoses get burst. Burst pressure is usually as four times as working pressure. Also, depending on the temperature, working and burst pressure might change.

Answer 6: By pouring the hot water into the hose, the part of water molecule goes into the PVC hose.

This is called moisture absorption. The hose looks like white if the water molecule goes into the PVC resin hose due to the fact that a refraction angle changes. If the hose turns white, there is no functional problem. Also, as time passes by, moisture evaporates. As a result, hose returns to the normal color. For your information, in addition to PVC, polyurethane (PU) and nylon have higher levels of moisture absorption.

Answer 7: Each hose/tube has a cut mark.

Answer 8: Although there are some differences among materials of the hose,

it is a good idea to select the fittings whose fittings are 1 - 2mm smaller against the outside diameter of the hose size. PVC hoses are more stretchable than other material hoses.

Answer 9: PVC hoses contain the plasticizer. The plasticizer itself is a feed for bacteria to breed mold.

If you would like to solve this problem, we strongly recommend you to adopt non-PVC hoses.

Non-PVC hoses do not contain the plasticizer. Please select either "KY Hose Series" or "Flexible Fluorine Resin Hose Series."

Answer 10: Hose contains reinforced materials such as yarn and spring wire. On the other hand, tubing does not contain any reinforced material.

Answer 11: Both PVDF and ETFE are types of fluorine. Compared with PVDF fluorine, ETFE fluorine has greater chemical resistance. ETFE fluorine stands proof against some type os solvents such as Ketone and Acetone.

Answer 12: Fluorine is a material, which shows high chemical resistance, non-adhesiveness, and water-repellent properties.

Answer 13: PVC hose is originally very soft, because it contains plasticizer. However, plasticizer gradually flows out as the hose transfers oil or the hose exposed to the sun. Once the certain amount of plasticizer flows out, the hose turns hard.

Answer 14: A multi-layer tube or hose allows to add more than one function. For instance, customers have used teflon tube for high chemical resistance. However, they suffer from the problem of hardness.

Our E-SJ, which is made of ETFE fluorine and PU, has both characteristics: high chemical resistance and flexibility.

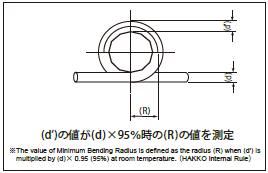

Answer 15: Minimum bend radius is NOT equal to product softness (flexibility). The value of Minimum Bend Radius is defined as the radius (R) when (d') is multiplied by 95% at room temperature (HAKKO Internal Rule). Thus, Minimum Bend Radius is the index to measure the flatness of the tubing or hose. The more flat the tubing or hose is, the less likely the fluid is to flow.

Answer 16: Yes, please refer to the following table. Unit A is almost equal to Unit B.

| Unit A | Unit B |

| 1 MPa | 10 Bar |

| 1 MPa | 1,000 kPa |

| 1 MPa | 145 PSI |

| 1 meter | 3.28 feet |

| 1 feet | 0.3 meter |

Answer 17: UL94 is a "Test for Flammability of Plastic Materials for Parts in Devices and Appliances." There are six flammability standards (UL94-5VA, UL94-5VB, UL94-V0, UL94-V1, UL94-V2 and UL94-HB). UL94-5VA is the most inflammable standard, while UL94-HB is the most flammable standard. We can produce a hose/tubing that meets your required flammable standard.

Answer 18: Pipe size is not always equal to our standard catalog size. For more information, please take a look at the following table.

| Size | Inner Diameter (mm) | Outer Diameter (mm) |

| 6 A | 6.5 | 10.5 |

| 8 A | 9.2 | 13.8 |

| 10 A | 12.7 | 17.3 |

| 15 A | 16.1 | 21.7 |

| 20 A | 21.6 | 27.2 |

| 25 A | 27.6 | 34.0 |

| 32 A | 35.7 | 42.7 |

| 40 A | 41.6 | 48.6 |

| 50 A | 52.9 | 60.5 |

Answer 19: First of all, we always recommend you to use our original fittings, as the matching between our hose and fittings is guaranteed. However, in case you have no choice but to use the fittings produced by other manufacturers, our recommendation is that a fitting outer diameter size should be about 5-15 % bigger than a hose inner diameter size. For instance, if you look for a suitable fitting for I.D. 12mm hose, the recommended outer diameter size of fittings should be between 12.6mm and 13.8mm. Please note that the recommended fitting outer diameter size varies, depending on the hose material (such as PVC, Nylon and Fluorine). If you are not sure about the appropriate selection of the fittings, please consult with us here. We are happy to guide you an appropriate solution.

Answer 20: If two or more chemicals are mixed, the chemical resistance chart is not reliable. (We are not sure about how two or more chemicals affect the material A.) Thus, we strongly recommend you to obtain the sample and test it in the application. Please request a sample here.

Answer: The thread made in Japan is based on ISO Standard. ISO Standard is compatible with BS Standard (UK Standard). However, NPT Standard (US Standard) is NOT compatible with ISO/BS Standards.

Answer 22: Yes. The Japanese Food Sanitation Law specifies the regulations for copper, lead, and their alloys in utensils, with lead content limited to 0.1% or less in tin used for plating, manufacturing, or repairing metal, and 5% or less in antimony. Since SUS is a material, specified in the JIS standards as containing neither lead nor antimony, we recommend SUS fittings for food and beverage applications.

Answer 23: "Anti-Static" [109 to 1013] means the ability to prevent the static electricity from accumulating. On the other hand, "Conductivity" [103 to 105] means the ability of an object to conduct the electricity. Compared to anti-static properties, "Conductivity" allows the static electricity to be dissipated instantly due to its low resistance. Simply put, "Conductivity" is more effective than "Anti-Static" properties in dissipating static electricity.

Made-to-Order Hose

Answer 1: Yes. In case you cannot find the appropriate hose, we can manufacture a made-to-order hose which is tailored to your needs. Please fill out the following form from below.

Answer 2: The minimum production lot varies depending on the hose size. Usually, the MOQ for production lot is 1,000m. However, we can manufacture a hose even if the quantity is not reaching the MOQ. Please request the quantity you need.

Answer 3: It usually takes at least one month to manufacture. However, if your hose requires special materials, the production lead time might be longer than one month. For more information on this made-to-order process, please visit "Made-to-Order Tube/Hose" webpage.

Regulations and Certificate

Answer 1: "SDS" ("MSDS") stands for "(Material) Safety Data Sheet." "Safety Data Sheet" is a material-based datasheet. If you need "SDS" ("MSDS"), please send your inquiry from here.

Answer 2: Yes, we can issue a certificate of RoHS 2 compliance. Please click here.

Answer 3: Yes, we can issue a certificate of REACH or SVHC. Please fill out the form from below.

Answer 4: Yes, we can issue this certificate upon request. Please send your request from this form.

Answer 5: Yes, you can download online. Please visit each product page and click "Food Grade Certificate Request."

Answer 6: No. HAKKO products are not certified with UL. However, we can provide a third-party UL certificate for some products. Please click here.

Answer 7: We are sorry to inform you that HAKKO catalog products are not compliant with FDA. However, we can produce a hose with FDA-approval materials. If you are interested in our custom-made hose with FDA approval, please contact us from here.

Answer 8: Yes. All HAKKO standard catalog products are DOP (DEHP) free.

Answer 10: PFOA is one of the environmental regulations. Due to the revision of REACH regulations, PFOA substances are strictly regulated under the certain threshold. HAKKO can check whether or not our products are compliant in PFOA regulations. Please send your inquiry from here by informing the part number and product name.

Answer 9: ATEX means "Potentially Explosive Atmosphere" (explosive atmosphere) in English. This terminology is often heard in the European Community (EC). However, as a hose itself, HAKKO cannot obtain the certificate of ATEX. Thus, customers need to apply for ATEX certificate as a unit, not a hose itself.

Answer 11: The following 10 substances are restricted according to the RoHS2 regulation:

(A) Cadmium [Cd] 0.01% (100ppm) or less

(B) Mercury [Hg] 0.1%(1,000ppm) or less

(C) Lead [Pb] 0.1%(1,000ppm) or less

(D) Hexavalent Chromium [Cr6+] 0.1%(1,000ppm) or less

(E) Polybrominated Biphenyls [PBB] 0.1%(1,000ppm) or less

(F) Polybrominated Diphenyl Ethers [PBDE] 0.1%(1,000ppm) or less

(G) Phthalate [DIBP] 0.1%(1,000ppm) or less

(H) Di-2 Ethylhexyl Phthalate [DEHP] 0.1%(1,000ppm) or less

(I) Benzyl phthalate [BBP] 0.1%(1,000ppm) or less

(J) Phthalate [DBP] 0.1%(1,000ppm) or less

If you need a certificate on this, please visit this webpage.

Answer 12: CE marking (UKCA marking) is not applicable to plastic hoses/tubing and metal fittings. Thus, we cannot issue the certificate.

Answer 13: Yes, we can issue a PPAP document. Please send your inquiry from here.