FDA Flexible Nylon Tubing Clear [Model Number: N-TU-CL-FDA]

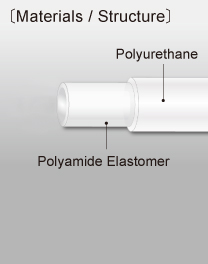

Multi-Purpose | Chemical, Ink, and Solvent Resistant, FDA 21 CFR Compliant, Flexible, and Soft Tubing [Inner Layer: Polyamide [PA] (FDA Grade) and Outer Layer: Polyurethane [PU] (FDA Grade)]

Fluids

chemicals

chemicals flux

flux food

food drink

drink cosmetics

cosmetics alcohol

alcohol Applications

- For Transferring Chemicals used in Laboratory Equipment

- For Transferring Beverage and Food

- For Transferring Fatty Acid Ester such as Biofuel (BDF)

- For Transferring Chemical and Industrial Wastes

- For Transferring Alcohol, Cosmetics, and Chemicals

- For Transferring Chemicals used in Medical Equipment

- For Filling Line of Fragrance, Colorant, and Additive

- For Air Supplying Pipes at Clean Room

Functions

Solvent Resistance

Non-PVC

Chemical Resistance

Low Elution

Low Odor

Food-Sanitation

Flexibility

Gas Barrier

Non-Phthalic Acid

Cold Resistance

Alcohol Resistance

FDA Compliant

Characteristics

- Moderate Chemical Resistance...Since the inner layer is made of polyamide (nylon), it shows moderate levels of chemical resistance.

- Flexibility...Due to the laminated structure, compared with a single-layer nylon tubing, N-TU-CL-FDA is superior in flexibility. This improves your work efficiency.

- Hard to Break...Unlike a single-layer nylon tubing, N-TU-CL-FDA is less likely to break. (Even if it breaks, you can restore its shape to some extent.)

- Plasticizer-Free...N-TU-CL-FDA does not contain any plasticizer (elution material) at all. N-TU-CL-FDA is an oil-free tubing.

- Non-PVC...N-TU-CL-FDA is made of non-PVC materials.

- Low Elution and Low Odor...Since N-TU-CL-FDA contains very low levels of elution and odor, it is highly recommended for use in transfers of food, beverage, and cosmetics.

- Easy to Cut...Since we print the cut mark on the hose every meter, it is easy to cut into the length.

- Transparency...Unlike a Teflon tubing sold in the market, N-TU-CL-FDA enables you to check the fluid easily.

- Original Fittings...By using our original fittings, you can avoid accidents which are caused by incorrect choices of hose and fittings. For more information on our original fittings, please scroll down to the end.

Certificates and Regulations

- RoHS Compliant...N-TU-CL-FDA is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that N-TU-CL-FDA does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.) Certificate is available on request.

- EU REACH and UK REACH...N-TU-CL-FDA is compliant with REACH SVHC 31st list (242 substances). Certificate is available on request.

- Non-Use of UV-328...N-TU-CL-FDA does not contain UV-328. Certificate is available on request.

- TSCA (Toxic Substance Control Act) Compliance...N-TU-CL-FDA does not use decaBDE, PIP(3:1), 2,4,6-TTBT, PCTP and HCBD. Certificate is available on request.

- PFOA, PFOS, and PFAS-Free...N-TU-CL-FDA does not contain perfluorocarboxylic acids (PFCAs C 9 - C 14), their salts or PFCA-related substances. Certificate is available on request.

- FDA 21 CFR Certified...N-TU-CL-FDA is made of FDA CFR 21 certified materials. Certificate is available here.

Product Standard

*Standard Type*

*Soft Type*

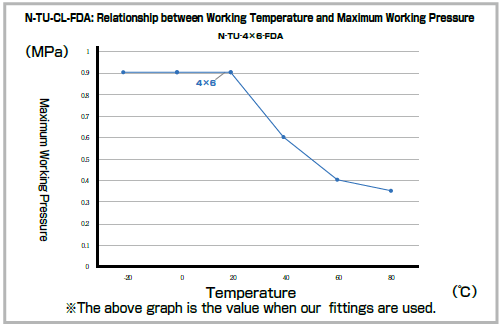

- Temperature Range : -20 - 80 $^\circ$C (-4$^\circ$F - 176$^\circ$F)

- Color : Clear

- One Roll Length: 100m

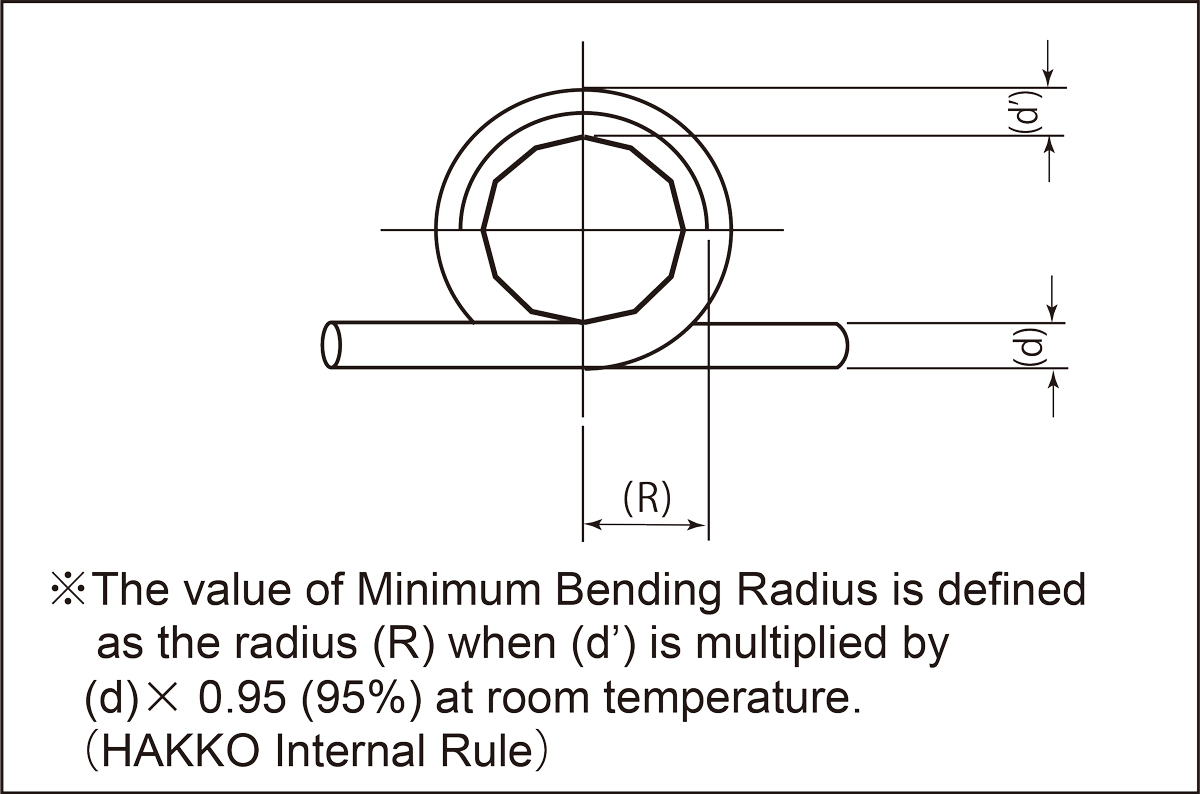

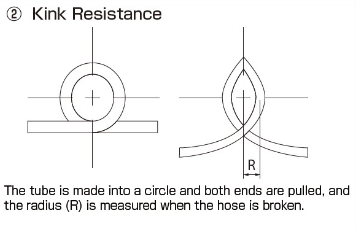

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please refer to the value of "Bending Stress Data" in the section of Technical Information or request the sample.

*If you are interested in the sizes that are not available on the table above, please fill out the following form. (We can produce a made-to-order size that is not listed on the table above.)

Made-to-Order Inquiry Form

Leaflet Request

For more information on our Product Standard of N-TU-CL-FDA, please click "Product Leaflet Download" above.

Cautions:

- In case you have to use your fittings other than our original fittings, due to the laminated structure tubing, please use the joints to seal an inner surface of the tubing. Please do not use the joints to seal an outer surface of the tubing. This may result in the bursting or coming off from the tubing.

- When you use our products, please refer to "Precautions for Use."

- In terms of chemical resistance, please refer to "Chemical Resistance Data." If you cannot find the chemical name or the fluid name, please contact us from this link.

- Although the inner layer is resistant to fluids, depending on working environments, the fluids would be permeated through the inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

Technical Information

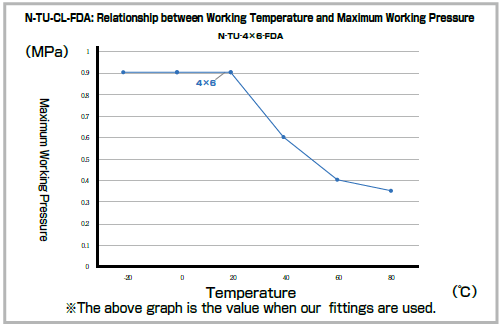

(A) Relationship Graph between Working Temperature and Maximum Working Pressure

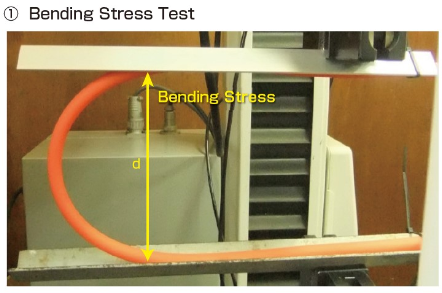

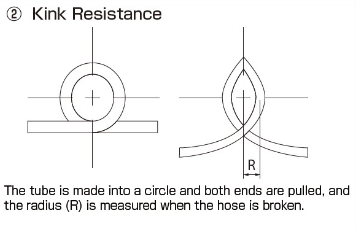

(B) Flexibility Comparative Data

d = 50 mm

Results: "Bending Stress" is one indication of flexibility. Flexibility varies depending on tubing. The smaller the value of bending stress is, the more flexible the tubing is. N-TU-CL-FDA is slightly harder than E-PD and E-SJ.

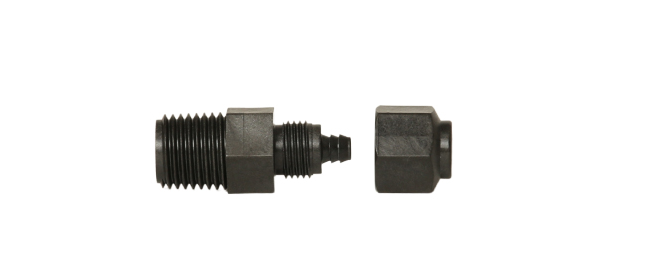

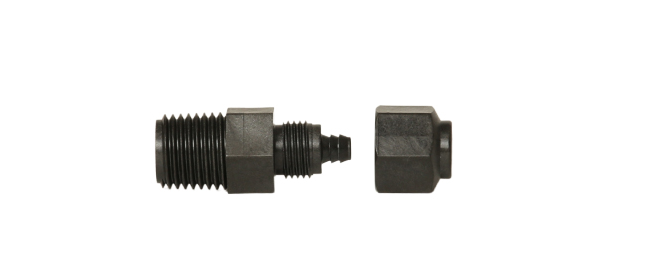

HAKKO Original Fittings for N-TU-CL-FDA

| Product Name | Materials, Characteristics |

| Fittings for Multi-Layer Tubing [Model Number: E-FTS-F]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|

| PEEK (Carbon Reinforced) Nut Type Fittings [Model Number: AL]] |

- Material: PEEK

- Lightweight...Fitting weight is less than one-fifth, compared to same-size SUS joints, leading to overall weight reduction of equipment.

- Great Heat Resistance...PEEK material has excellent heat resistance among resins.

- Chemical Resistance...PEEK material has excellent resistance to a wide range of chemicals including acids, alkalis and organic solvents.

- Mechanical Strength...Carbon fiber is added to the engineering plastic of PEEK, which is strong in tensile and impact resistance.

|

|