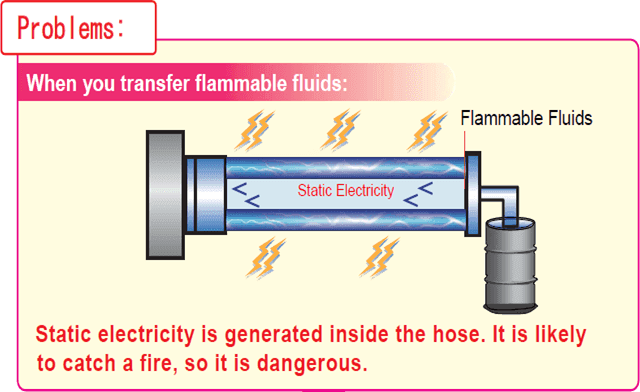

When transporting flammable liquids (combustible fluid), dealing with static electricity is necessary in all fields. (For instance, in the field of electronics, the compliance to ATEX requirements is absolutely necessary.) Hydrocarbon fluids (used in fuel oil and cleaning agents) are highly insulating and static fluids. In the dry winter, the measurement against the static electricity is absolutely required. For the transport of highly flammable liquids, we recommend you to use "Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type)." "Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type)" is the best solution for the streaming electrification generated inside the hose. (Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type) performs better than a hose with ground wire, in terms of non-charging static electricity.)

In order to understand "Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type)" more easily, please take a look at the short video clip of "Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type)."

Case Studies

A: Printing and Paint Customer

Fluids: Inks and Paints

Current Problems: Conductive rubber hose does not any chemical resistance. Internal cost goes up as the frequency of changing hose goes up.

Solutions: HAKKO recommends "E-SJSD: Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose (Dissipative Type)." This is because E-SJSD has the features of conductivity and solvent resistance. As a result of these features, the frequency of changing a hose is far less often.

B: Adhesive Customer

Fluids: Toluene (Organic Solvents)

Current Problems: This customer is currently using a teflon hose, but no measurements against the generation of static electricity are taken. It is possible to catch a fire.

Solutions: HAKKO recommends "E-SJSD: Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose (Dissipative Type)." This is because E-SJSD has the features of conductivity and solvent resistance. E-SJSD solves the problem of the generation of static electricity.

C: Fragrance and Aromatic Customer

Fluids: Gel

Current Problems: PVC hoses have been used, but the local authority demands that a hose has to have measurements against the generation of static electricity.

Solutions: HAKKO recommends "E-SJSD: Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose (Dissipative Type)." This is because E-SJSD has the features of conductivity and solvent resistance. E-SJSD meets the inspection requirements of the local authority.

D: Powder Customer

Fluids: Iron Powder

Current Problems: PVC hoses have been used, but the static electricity was generated after the friction of iron powder.

Solutions: HAKKO recommends "E-SJD: Flexible Fluorine (ETFE) Resin Tubing (Dissipative Type)." This is because E-SJD has the feature of conductivity. E-SJD solves the problem of static electricity.

If you would like to download a brochure of Flexible Fluorine (ETFE) Resin Hose Series (Dissipative Type), please download the brochure.

Frequently Asked Question on Why E-SJD/E-SJSD are suitable for Flammable Fluids

- In the technical specifications, issued by the International Electrotechnical Commission (IEC) as the "Safety Guide for Hoses," Guidelines for static electricity have been defined. (IEC/TS 60079 -32 -1: 2013 7.7.3 Hose and hose assembly). To minimize the danger from the static electricity and the stray current, the regulation on the classification of resistance exists between one end of the hose and the other end of the hose.

- These are used as the hose end-to-end resistance (R) standard, which is shown below:

- "Conductivity (R < 1 KΩ)"; "Dissipative (1 KΩ < R < 1 MΩ)"; "Insulation (1MΩ ≦ R)"

- Among these standards above, in the case of conductive (R < 1 KΩ) piping, it is easy to be affected by stray current and difficult to control at a safe level. Stray current leads to the situation that the current leaks from the electrical equipment to the ground. We think that this leakage is not acceptable. We believe that the “dissipative” level is the most appropriate. Thus, we recommend HAKKO E-SJD/SJSD, dissipative product series.

Electrical Properties of Major Flammable Fluids (Conductivity)

Insulating Fluid (<100 pS/m)

Fluid | Conductivity pS/m | Fluid | Conductivity pS/m |

|---|---|---|---|

| Anisole (Methylphenyl Ether) | 10 | Turpentine | 22 |

| Ethylbenzene | 30 | Diesel Oil Light Oil (Purified) | About 0.1 |

| Gasoline(Straight Run) | About 0.1 | Decalin | 6 |

| Gasoline(Unleaded) | <50 | Kerosene | 1 - 50 |

| Caprylic Acid (Octanoic Acid) | <37 | Toluene | <1 |

| Xylene | 0.1 | Carbon Disulfide (1$^\circ$C) (34$^\circ$F) | 7.8$\times$10-4 |

| Cyclohexane | <2 | Hexamethyldisilazane | 29 |

| Diethyl Ether | 30 | Hexane | 1$\times$10-5 |

| Jet Fuel(A,A-1,B) | 0.01 - 50 | Heptane | 3$\times$10-2 |

| 1,4-Dioxane (Diethylenedioxite) | 0.1 | Benzene | 5$\times$10-3 |

| Styrene Monomer | 10 |

Semi-Conductive Fluid (100 - 10,000 pS/m)

Fluid | Conductivity pS/m | Fluid | Conductivity pS/m |

|---|---|---|---|

| 2-Ethylhexyl Acrylate | 610 | Pentyl 1-Acetate (- Amyl.) (23$^\circ$C) (73$^\circ$F) | 2160 |

| Butyl Acrylate (Butyl Acrylate) | 3580 | n-Butyl Acetate (23$^\circ$C) (73$^\circ$F) | 4700 |

| Isopropyl Ether | 500 | n-Propyl Acetate (4$^\circ$C) (39$^\circ$F) | 8460 |

| 2-Ethylhexyl Alcohol | 7900 | 1,2,4-Trichlorobenzene | 200 |

| Gasoline (lead) | About 100 | Butyl Propionate | 2300 |

| Chlorobenzene | 7000 | Propionic Acid (25$^\circ$C) (77$^\circ$F) | 8500 |

| Dichloroethylene | 4000 | 1-Bromonaphthalene | 3660 |

| Isobutyl Acetate (23$^\circ$C) (73$^\circ$F) | 4320 | Bromobenzene | 1200 |

Conductive Fluid (>10,000 pS/m)

Fluid | Conductivity pS/m | Fluid | Conductivity pS/m |

|---|---|---|---|

| Ethyl Acrylate | 3.35$\times$105 | Ethyl Acetate (23$^\circ$C) (73$^\circ$F) | 4.6$\times$104 |

| Acrylonitrile | 7$\times$105 | Vinyl Acetate (23$^\circ$C) (73$^\circ$F) | 2.6$\times$104 |

| Acetaldehyde (15$^\circ$C) (59$^\circ$F) | 1.7$\times$108 | Diethanolamine (20$^\circ$C) (68$^\circ$F) | 4.6$\times$107 |

| Acetone (25$^\circ$C) (77$^\circ$F) | 6$\times$106 | Diethylketone | 5.2$\times$107 |

| Aniline | 2.4$\times$106 | Diethylerin Glycol | 5.86$\times$107 |

| Allyl Alcohol | 7$\times$108 | Cyclohexanone | 5$\times$105 |

| Isoamyl Alcohol | 1.4$\times$105 | Dichloroethane | 2.0$\times$105 |

| Isopropyl alcohol (25$^\circ$C) (77$^\circ$F) | 3.5$\times$108 | Dimethylformamide | 6$\times$106 |

| Ethanolamine | 1.1$\times$109 | Tetrahydrofuran | 3.3$\times$105 |

| Ethylamine (0$^\circ$C) (32$^\circ$F) | 4$\times$107 | Triethylene Glycol | 8.4$\times$106 |

| Ethyl Alcohol (25$^\circ$C) (77$^\circ$F) | 1.35$\times$105 | Nitrobenzene (0$^\circ$C) (32$^\circ$F) | 5$\times$105 |

| Ethyleneimine | 8$\times$108 | Pyridine (18$^\circ$C) (64$^\circ$F) | 5.3$\times$106 |

| Ethylene Glycol | 1.16$\times$108 | n-Butyl Alcohol (25$^\circ$C) (77$^\circ$F) | 2.0$\times$107 |

| Ethylenediamine | 9$\times$106 | Furfural (25$^\circ$C) (77$^\circ$F) | 1.5$\times$108 |

| Epichlorohydrin (25$^\circ$C) (77$^\circ$F) | 3.4$\times$106 | n-Propyl Alcohol (25$^\circ$C) (77$^\circ$F) | 2$\times$106 |

| Formic Acid (25$^\circ$C) (77$^\circ$F) | 6.4$\times$109 | Benzyl Alcohol (25$^\circ$C) (77$^\circ$F) | 1.8$\times$108 |

| Ethyl Formate | 1.45$\times$105 | n-Methyl -2 pyrrolidone | 2$\times$106 |

| Methyl Formate | 1.92$\times$108 | Methyl Alcohol (18$^\circ$C) (64$^\circ$F) | 4.4$\times$107 |

| Quinoline | 2.2$\times$106 | Methylisobutyl Ketone | <5.2$\times$106 |

| Glycerin (25$^\circ$C) (77$^\circ$F) | 6.4$\times$106 | Methyl ethyl ketone (25$^\circ$C) (77$^\circ$F) | 1$\times$107 |

| M-cresol | 1.397$\times$106 | Methylformamide | 8$\times$107 |

| Chlorohydrin (25$^\circ$C) (77$^\circ$F) | 5$\times$107 | Monoethanolamine (MEA/20$^\circ$C) | 1.2$\times$109 |

| Acetic Acid (25$^\circ$C) (77$^\circ$F) | 1.12$\times$106 | - |