Flexible Fluorine (ETFE) Resin Tubing (Dissipative Type) [Model Number: E-SJD]

Multi-Purpose / Chemical Resistance Tube | NEW! Electrical Resistivity of Hose is compliant with international standards. You can mitigate static electricity when you transfer flammable fluids.

Fluids

chemicals

chemicals ink

ink paint

paint flux

flux UVpaint

UVpaint UVink

UVink food

food drink

drink powder

powder inflammable

inflammable Applications

- Piping for Preventing Static Electricity

- For Transferring Flammable Fluids at Chemical Factories

- For Transferring High Volatile Fluids such as Alcohol and Fragrance

- For Transferring Paints and Solvents

Functions

Conductive

Solvent Resistance

Non-PVC

Non-Adhesiveness

Chemical Resistance

Low Odor

Food-Sanitation

UV Cut

Oil-Proof

Alcohol Resistance

UL Compliant

Characteristics

- Chemical Resistance...Since the inner layer is made of ETFE Fluorine Resin, E-SJD stands proof against most of the chemical substances.

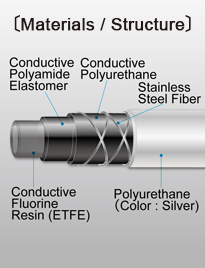

- Dissipative...Due to the use of conductive resin and metal fiber, no matter how long a hose is, electrical resistivity (Conductive: Dissipative Grade) is achieved.

- Compliance with Guideline...The value of electrical resistivity is compliant with ISO 8031 and IEC/TS 60079-32-1: 2013 (Explosive Atmosphere: Part 32-1 : Guideline for Dangerous Static Electricity).

- Higher Non-Adhesiveness...Since ETFE fluorine resin is superior in terms of non-adhesiveness, you can wash out the fluids very easily.

- Plasticizer-Free...E-SJD does not contain plasticizer (an elution material) at all. E-SJD is an oil-free hose.

- UV Cut...E-SJD can shield the ultraviolet (Wavelength: from 240nm to 800nm) over 99%.

- Original Fittings...By using our original fittings, you can avoid accidents which are caused by incorrect choices of hose and fittings. For more information on our original fittings, please scroll down to the end.

Certificates and Regulations

- RoHS Compliant...E-SJD is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that E-SJD does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.) Certificate is available on request.

- UL94HB Equivalent...According to the third-party institution test, E-SJD is confirmed as equivalent to UL94HB (Flame Retardancy Test UL94HB Horizontal Combustion Test). Certificate is available on this webpage.

- Non-Use of UV-328...E-SJD does not contain UV-328. Certificate is available on request.

- Food Sanitation Act Compliant...E-SJD conforms to the Food Sanitation Act No.380 (No.380 of the Ministry of Health and Welfare for Food Sanitation) (Conformity to N-Heptane) and the Food Sanitation Act No.324 (Positive List System) [No.324 of the Ministry of Health, Labour, and Welfare]. Regarding the conformity of the Food Sanitation Act No.324 (Positive List System), please download the certificate.

Packing Images

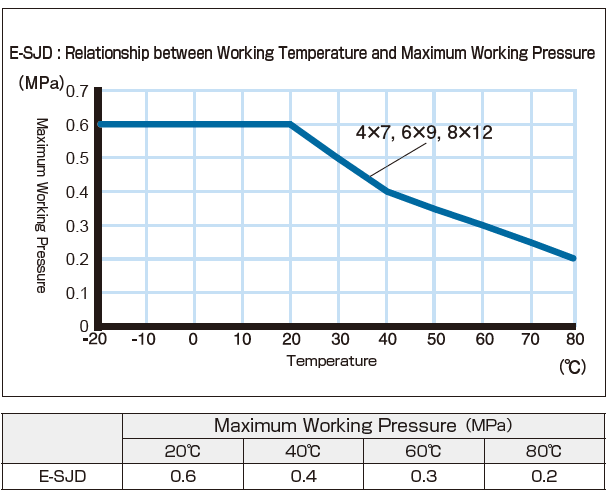

Product Standard

- Temperature Range : -20 - 80 $^\circ$C (-4$^\circ$F - 176$^\circ$F)

- Color : Silver

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please contact us and request the sample.

Leaflet Request

For more information on our Product Standard of E-SJD, please click "Product Leaflet Download" above.

Specification Request

For more technical information (such as Thickness of Each Layer and Precautions in Use) on E-SJD, please click "Product Specification Download" above.

Cautions:

- Due to the laminated structure tubing, please use the joints to seal an inner surface of the hose.

- Please do not use the joints to seal an outer surface of the hose. This may result in the bursting or coming off from the hose.

- When you use our products, please refer to "Precautions for Use." ("The Precautions for Use" of E-SJD is also downloadable here.)

- In terms of chemical resistance, please refer to "Chemical Resistance Data."

- Although the inner layer is made of ETFE fluorine, please make sure whether or not E-SJD is usable for high purity fluids before you use.

- Although the inner layer is resistant to fluids, depending on working environments, the fluids would be permeated through the inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

- Flexible Fluorine (ETFE) Resin Tubing (Dissipative Type) do not have the function of getting rid of already charged fluids. Please take another approach to deal with.

- Regarding the original fittings for Flexible Fluorine (ETFE) Resin Tubing (Dissipative Type) [E-SJD], if the tubing is NOT used in the fixed pipe, we recommend you to choose E-FTS-GN: Fittings for Multi-Layer Tubing (with Tubing Guide).

- Since "Flexible Fluorine (ETFE) Resin Tubing (Dissipative Type)" contains carbon, its durability against repeated bending stress is inferior to that of the "Flexible Fluorine Resin Hose Series." Depending on the conditions of repeated bending, it may cause cracking. Thus, we kindly request customers to verify the product about whether or not it can be used.

Case Study

Problem: Conductive rubber hose is not sufficient in terms of chemical resistance.

Company A has been using conductive rubber hose, but due to its low chemical resistance, Company A has to replace the hose frequently, leading to lower production and increase of the maintenance costs.

HAKKO Solution:

HAKKO proposed E-SJD: Flexible Fluorine (ETFE) Resin Tubing (Dissipative Type) and provided a sample. An inner layer of E-SJD is made of conductive ETFE fluorine. A middle layer is made of conductive polyurethane with stainless steel fiber. The inner layer shows higher levels of chemical resistance. Also, E-SJD is a perfect tubing composition to deal with the generation of the static electricity. As a result, after Company A evaluates our E-SJD, Company A is satisfied with the chemical resistance and anti-static levels of E-SJD.

Frequently Asked Questions

Question: What is the characteristic of E-SJD?

Answer: E-SJD meets the international guideline on static electricity. With special structures of the hose, E-SJD prevents the generation of static electricity, resulting in the creation of safe work environment. If you transport high flammable fluid, we strongly recommend you to consider E-SJD.

Question: We would like to use E-SJD-6x9 and E-FTS-6×9-R1/4. If the seal tape is attached around the screw part to prevent the leakage, the resistance value will go up. Do you have any solutions on this?

Answer: There are three possible solutions. 1: Insert the ground wire between the HEX part and the nut of E-FTS and tighten the nut. (However, please note that grounding is possible, but the nut is not tightened to the end part. Thus, the tightness and pressure resistance may be lowered. 2: Wrap the ground wire around the R-threaded portion of E-FTS. (Wrap the ground wire between the HEX part of E-FTS and the equipment where R screw is installed.) 3: Wrap the ground wire around E-FTS main body of HEX Part.

Question: What does "Dissipative" mean?

Answer: "Dissipative" is one of the classifications of surface resistivity. In terms of electrical resistivity, "Conductive" is defined as 10³~10⁵Ω-m, "Dissipative" is defined as 10⁶~10⁸Ω-m and "Anti-Static" is defined as 10⁹~10¹³Ω-m. For the purpose of suppressing the levels of static electricity, it is said that "Conductive" comes first, "Dissipative" comes next, and "Anti-Static" comes last.

Technical Information

(A) Relationship Graph between Working Temperature and Maximum Working Pressure

(B) Resistance Value by Hose Length

Measurement method: HAKKO original fittings are attached to both ends, and the resistance value between the fittings is measured by an insulation resistance meter. (However, in order to accurately measure the resistance value for a product with conductive line layers, please do not attach the lead rods on the line layer.)

Notes: The data above are the test values and are not guaranteed values.

(C) Leach Test Data

*Test Method: JIS S 3200-7: 2004 [Equipment for Water Supply Service]

Notes: The data above are the test values and are not guaranteed values.

Electrical Properties of Major Flammable Fluids (Conductivity)

The following information is cited from "Industrial Safety and Health Research Institute Technical Guidance on Electrostatic Safety Guide 2007 ISSN 1882 -2703 JNIOSH-TR-NO. 42 (2007) page 157 - 162 G.5."

Insulating Fluid (<100 pS/m)

HAKKO Original Fittings for E-SJD

| Product Name | Materials, Characteristics |

| Fittings for Multi-Layer Tubing (with Tubing Guide) [Model Number: E-FTS-GN]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|

| Fittings for Multi-Layer Tubing [Model Number: E-FTS-F]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|