Flexible Fluorine (ETFE) Resin Tubing (Ultra Soft Type) [Model Number: E-SJUS]

Multi-Purpose, Very Soft Tubing | Chemical Resistance Tubing | Single-layer teflon tubing is hard (stiff) and easy to break. Our Flexible Fluorine (ETFE) Resin Tubing (Ultra Soft Type) is an alternative, soft tubing for a teflon tubing.

*Note: Regarding the product marking color, the marking color will be changing from blue to orange for production after October 1, 2025. However, depending on our stocks, some sizes may have the previous marking color (blue color) even after October 1, 2025. Except this product marking color change, please be reassured that the product specifications remain the same. For more information, please download the official notice.

Fluids

chemicals

chemicals ink

ink paint

paint flux

flux food

food drink

drink cosmetics

cosmetics alcohol

alcohol Applications

- For Industrial Ink-Jet Printers (For Ink-Supplying Pipes)

- For Transferring Solvent-Based Inks

- For Transferring Paints, Solvents and Adhesives

- For Transferring Chemicals used in Laboratory Equipment

- For Transferring Chemicals used in Semiconductor-Related Devices and Flat Panel Display (FPD) Manufacturing Devices

- For Transferring Fatty Acid Ester such as Biofuel (BDF)

- For Transferring Chemical and Industrial Wastes

- For Transferring Alcohol, Cosmetics and Chemicals

- For Transferring Chemicals used in Medical Equipment, Endoscope and so on

- For Transferring Chemicals used in Manufacturing Fuel Cell and Pure Water

- For Printing Head, Wide-Format Ink-Jet Printers, Textile Printers, Ceramic Tile Printers, 3D Printers

- For Filling Line of Paints and Adhesives

- For Filling Line of Fragrance, Colorant and Additive

- For Air Supplying Pipes at Clean Room

Functions

Solvent Resistance

Non-PVC

Non-Adhesiveness

Chemical Resistance

Low Elution

Food-Sanitation

Flexibility

Oil-Proof

Cold Resistance

Alcohol Resistance

Ultra Soft

Characteristics

- Chemical Resistance...Since the inner layer is made of ETFE fluorine resin, E-SJUS is resistant to most of the chemical substances. For more information, please refer to chemical resistance data.

- Flexibility and Easy Handling...Due to the laminated structure, compared with a single-layer fluorine tubing, E-SJUS is superior in flexibility. This improves your work efficiency.

- Easy Fitting Installation...Since E-SJUS is very flexible, it is easier to install the tubing into the fittings.

- Hard to Break...Unlike a single-layer fluorine tubing, E-SJUS is less likely to break. (Even if it breaks, you can restore its shape to some extent.)

- Higher Non-Adhesiveness...Since ETFE fluorine resin is superior in terms of water-proof, you can wash out the fluids very easily.

- Abrasion Resistance...Fluorine resin (inner layer) shows high levels of abrasion resistance. Thus, you can even transfer chemical slurry.

- Plasticizer-Free...E-SJUS does not contain plasticizer (an elution material) at all. E-SJUS is an oil-free tubing.

- Non-PVC...E-SJUS is made of non-PVC materials.

- Low Elution and Low Odor...Since E-SJUS contains very low levels of elution and odor, it is highly recommended for use in transfers of cosmetics.

- High Purity...Fluorine resin does not contain any additives such as plasticizer, so E-SJUS is suitable for transferring high purity chemical fluids.

- Easy to Cut...Since we print the cut mark on the hose every meter, it is easy to cut the length you would like to.

- Transparency...E-SJUS enables you to check the fluid very easily.

- Original Fittings...By using our original fittings, you can avoid accidents which are caused by incorrect choices of hose and fittings. For more information on our original fittings, please scroll down to the end.

Certificates and Regulations

- RoHS Compliant...E-SJUS is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that E-SJUS does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.) Certificate is available on request.

- EU REACH and UK REACH...E-SJUS is compliant with REACH SVHC 33rd list (250 substances). Certificate is available on request.

- Non-Use of UV-328...E-SJUS does not contain UV-328. Certificate is available on request.

- Food Sanitation Act Compliant...E-SJUS conforms to the Food Sanitation Act No.380 (No.380 of the Ministry of Health and Welfare for Food Sanitation) (Conformity to N-Heptane) and the Food Sanitation Act No.324 (Positive List System) [No.324 of the Ministry of Health, Labour, and Welfare]. Regarding the conformity of the Food Sanitation Act No.324 (Positive List System), please download the certificate.

- Regulation (EC) No 1935/2004 and (EU) No 10/2011...An inner layer of E-SJUS is compliant with (EC) No 1935/2004 and (EU) No 10/2011.

- Compliance with ADI/TSE/BSE Free...An inner layer of E-SJUS does not contain ADI, TSE, and BSE.

- Compliance with BPA Free...E-SJUS does not contain BPA (Bisphenol A) (CAS No.80-0-7).

Packing Images

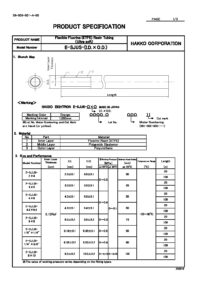

Product Standard

Standard Size

Made-to-Order Size

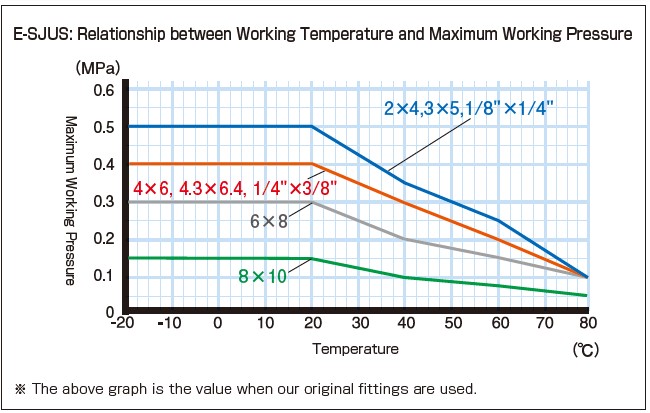

- Temperature Range : -20 - 80 $^\circ$C (-4$^\circ$F - 176$^\circ$F)

- Color : Clear

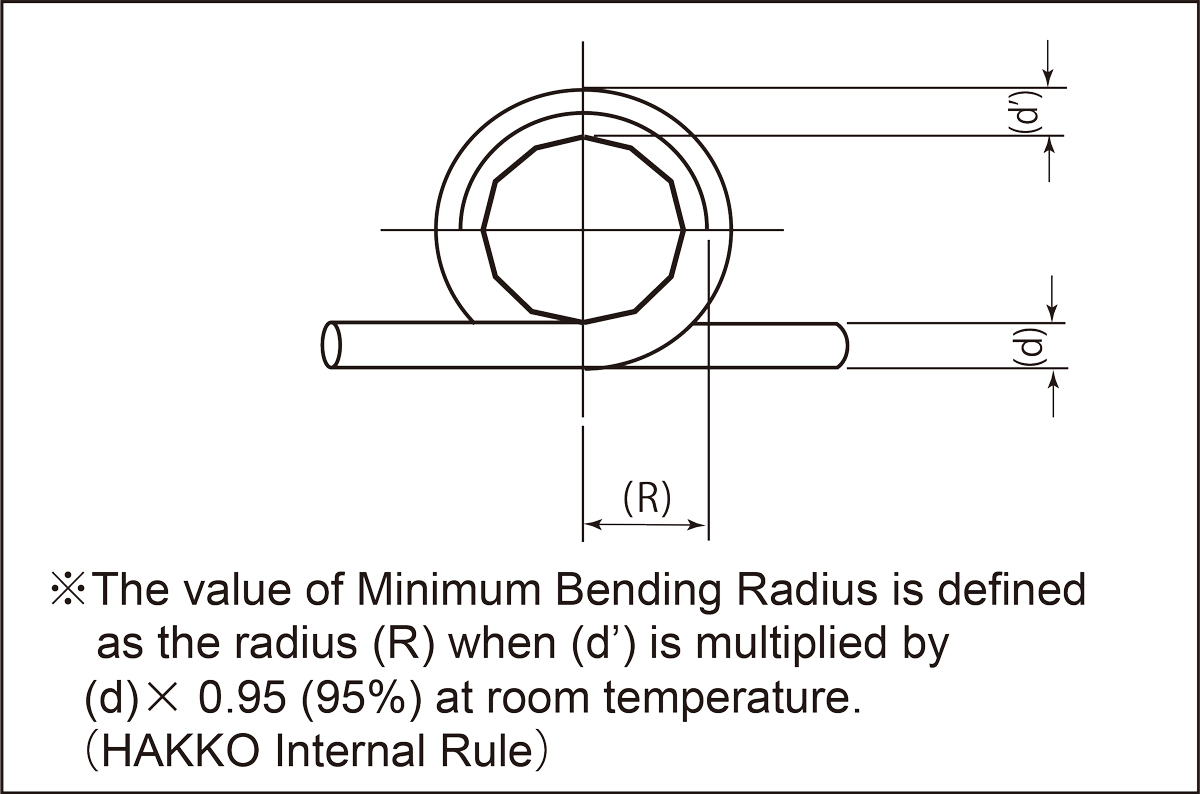

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please refer to the value of "Amount of Deflection" in the section of Technical Information or request the sample.

*If you are interested in non-standard, made-to-order size, please fill out the following form. (We can also produce a special size that is not listed on the table above. Please note that MOQ applies for made-to-order size.)

Made-to-Order Inquiry Form

Leaflet Request

For more information on our Product Standard of E-SJUS, please click "Product Leaflet Download" above.

Specification Request

For more technical information (such as Thickness of Each Layer and Precautions in Use) on E-SJUS, please click "Product Specification Download" above.

Cautions:

- We do not have our original fittings for E-SJUS-4.3$\times$6.4 and E-SJUS-8$\times$10.

- We do not have our original fittings for E-SJUS-1/8"$\times$1/4" and E-SJUS-1/4"$\times$3/8". If you need our technical support in selecting the suitable fittings for these sizes, please fill out this form.

- In case you have to use your fittings other than our original fittings, due to the laminated structure tubing, please use the joints to seal an inner surface of the tubing. Please do not use the joints to seal an outer surface of the tubing. This may result in the bursting or coming off from the tubing.

- When you use our products, please refer to "Precautions for Use." ("The Precautions for Use" of E-SJUS is also downloadable here.)

- In terms of chemical resistance, please refer to "Chemical Resistance Data."

- Although the inner layer is made of ETFE fluorine, please make sure whether or not E-SJUS is usable for high purity fluids before you use.

- Although the inner layer is resistant to fluids, depending on working environments, the fluids would be permeated through the inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

- White powder (Low Molecular Weight in Resin) might come out on the tubing during storage. This white powder conforms to the "Positive List System of the Revised Food Sanitation Law" (effective on June 1, 2020), so there is no safety problem. Please wipe it off before use.

Case Study

Situation: We look for a softer fluorine product like a fluorine rubber tubing.

An ink-jet printing manufacturer (called "Company A" hereinafter) was looking for a flexible fluorine tubing like a fluorine rubber tubing for better handling and confined-space installation. So far, Company A has adopted a fluorine rubber tubing, but due to the product supply shortage, Company A had to look for the alternative product.

HAKKO Solution:

HAKKO proposed E-SJUS: Flexible Fluorine (ETFE) Resin Tubing (Ultra Soft Type) and provided a sample. Company A was surprised that E-SJUS, a non-rubber fluorine tubing, is so soft. Company A conducted the ink matching test, and it turned out that the result of E-SJUS is better than that of fluorine rubber tubing. They decided to use E-SJUS for their ink-jet printing machine.

Frequently Asked Question

Question: E-SJUS is a multi-layer tubing. Is it easier to peel off the layer?

Answer: No. Even though E-SJUS consists of multi-layers, the inner layer and the outer layer are greatly adhered each other. Thus, you do not have to worry about delamination.

Technical Information

(A) Relationship Graph between Working Temperature and Maximum Working Pressure

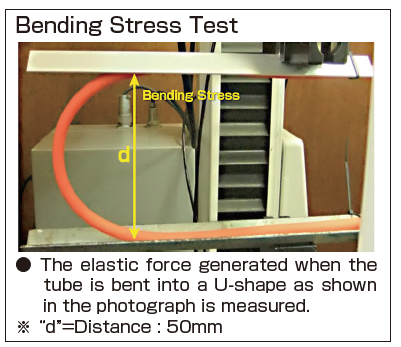

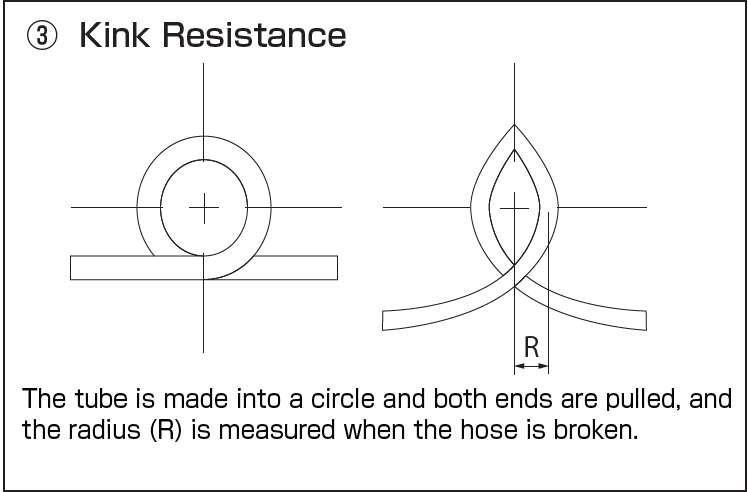

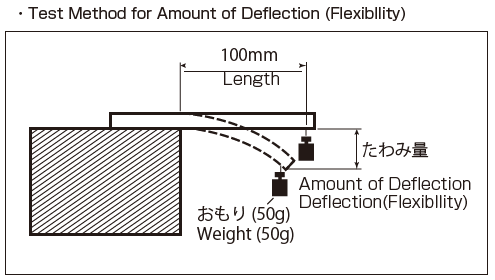

(B) Flexibility, Minimum Bend Radius, Kink Resistance and Amount of Deflection Data

Results: "Bending Stress Value" is one indication of flexibility. The smaller the value of bending stress is, the more flexible the hose (tubing) is. E-SJUS is much more flexible than E-SJ. On the other hand, E-SJUS values of minimum bend radius and kink resistance are larger than E-SJ values. This suggests that minimum bend radius has nothing to do with the flexibility.

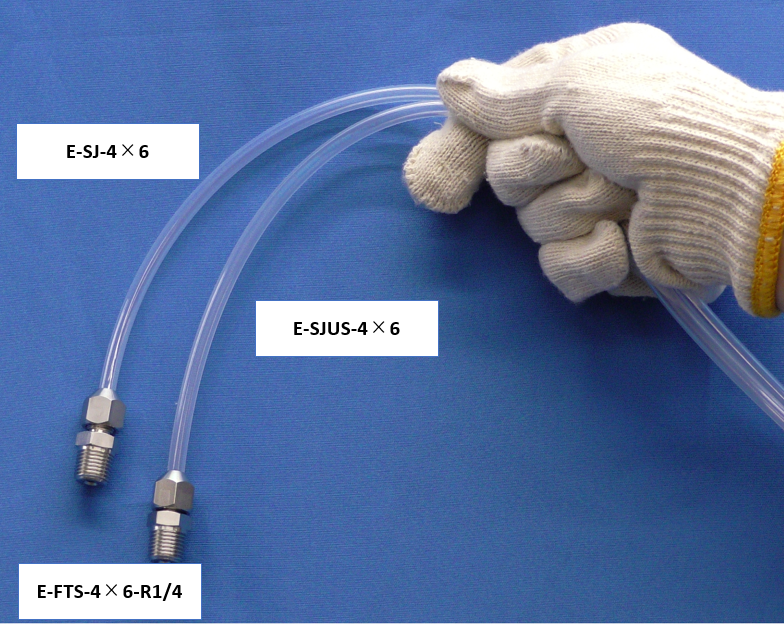

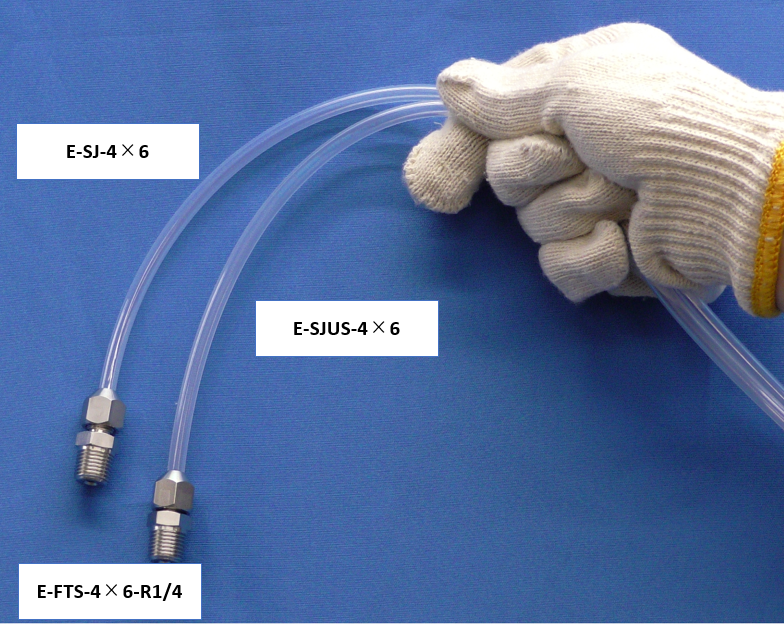

(C) Flexibility Difference Image (E-SJUS vs. E-SJ)

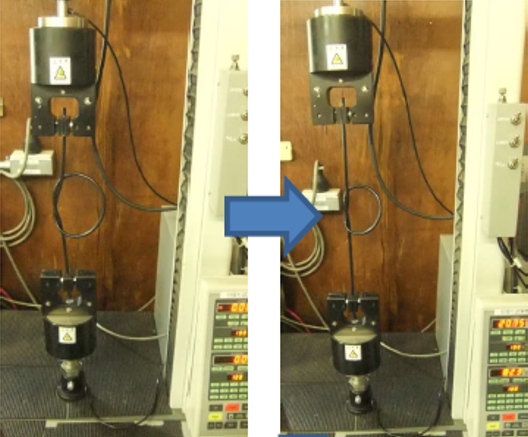

(D) Outer Layer Surface Smoothness Test (E-SJUS vs. E-SJ)

Background: Polyurethane resin has a feature of great abrasion resistance, but it has a feature of grip feeling. Thus, work efficiency becomes lower due to the adhesion of a tubing.

Testing Methods: Tie a tubing of E-SJ and E-SJUS, make its radius to 100mm, and then hold with an air chuck at both ends. After holding, measure the resistance value when the air chuck is pulled at the certain speed. Please see the picture below. (Please note that at the below picture, the test was conducted with E-SJUS-BK and E-SJ-BK.)

Results: The outer layer resistance value of E-SJUS is about one-fifth smaller than that of E-SJ. This indicates that E-SJUS shows higher outer layer smoothness than E-SJ, which greatly improves the work efficiency. This is due to the fact that an outer layer of E-SJUS uses a soft, smooth grade of polyurethane.

(E) Non-Adhesiveness Comparison Data

Critical Surface Tension: The surface tension of the assumed fluid which has the contact angle of zero against solid.

Results: Since the lower value of "Critical Surface Tension" and higher value of "Contact Angle for Water" show higher non-adhesivenss, ETFE fluorine material shows the highest non-adhesiveness.

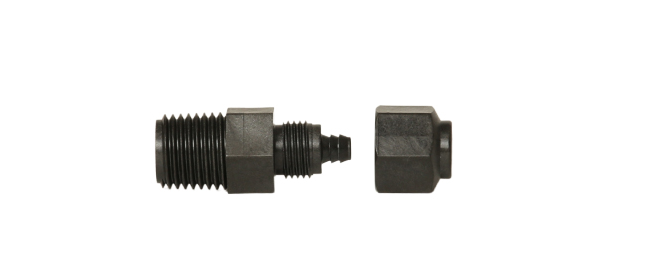

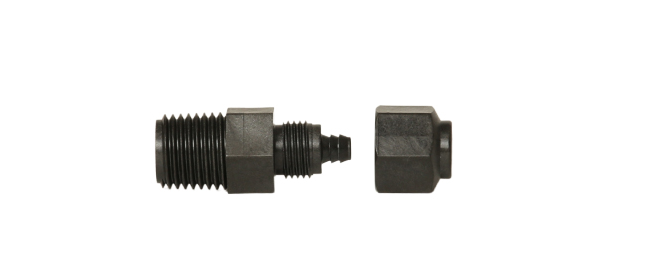

HAKKO Original Fittings for E-SJUS

| Product Name | Materials, Characteristics |

| Fittings for Multi-Layer Tubing [Model Number: E-FTS-F]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|

| PEEK (Carbon Reinforced) Nut Type Fittings [Model Number: AL]] |

- Material: PEEK

- Lightweight...Fitting weight is less than one-fifth, compared to same-size SUS joints, leading to overall weight reduction of equipment.

- Great Heat Resistance...PEEK material has excellent heat resistance among resins.

- Chemical Resistance...PEEK material has excellent resistance to a wide range of chemicals including acids, alkalis and organic solvents.

- Mechanical Strength...Carbon fiber is added to the engineering plastic of PEEK, which is strong in tensile and impact resistance.

|

|