Specification: Applicable Hose Size

Model Number | I.D.$\times$O.D. (mm) | Fitting Model | Working Pressure (MPa) | Temperature Range |

|

20$^\circ$C | 80$^\circ$C | $^\circ$C |

|||

E-SJ-2$\times$4 E-SJ-2$\times$4-BK E-SJ-2$\times$4-CBU E-PD-2$\times$4 | 2$\times$4 | E-FTS-2$\times$4-R1/8 | 0 - 0.6*(A) | 0 - 0.2 | -20 - 80 |

E-SJ-3$\times$5 E-SJ-3$\times$5-BK E-SJ-3$\times$5-CBU | 3$\times$5 | E-FTS-3$\times$5-R1/4 |

|||

E-SJ-4$\times$6 E-SJ-4$\times$6-BK E-SJ-4$\times$6-CBU E-PD-4$\times$6 E-SJUS-4$\times$6 E-SJUS-4$\times$6-BK | 4$\times$6 | E-FTS-4$\times$6-R1/4 |

|||

E-SJ-5$\times$7-BK | 5$\times$7 | E-FTS-5$\times$7-R1/4 | 0 - 0.5 |

||

E-SJ-6$\times$8 E-SJ-6$\times$8-BK E-SJ-6$\times$8-CBU E-PD-6$\times$8 E-SJUS-6$\times$8 E-SJUS-6$\times$8-BK | 6$\times$8 | E-FTS-6$\times$8-R1/4 | 0 - 0.4*(B) |

||

E-SJ-6$\times$9 E-SJ-6$\times$9-CBU E-SJD-6$\times$9 E-PD-6$\times$9 | 6$\times$9 | E-FTS-6$\times$9-R1/4 | 0 - 0.6 |

||

E-SJ-8$\times$12 E-SJ-8$\times$12-BK E-SJ-8$\times$12-CBU E-SJD-8$\times$12 E-PD-8$\times$12 | 8$\times$12 | E-FTS-8$\times$12-R3/8 |

|||

70$^\circ$C | |||||

E-SJV-6$\times$9 | 6$\times$9 | E-FTS-6$\times$9-R1/4 | 0 - 0.3 | 0 - 0.15 | 0 - 70 |

E-SJV-8$\times$12 | 8$\times$12 | E-FTS-8$\times$12-R3/8 |

|||

E-KYT-2$\times$4 | 2$\times$4 | E-FTS-2$\times$4-R1/8 | 0 - 0.2 | 0 - 0.05 | 0 - 70 |

E-KYT-3$\times$5 | 3$\times$5 | E-FTS-3$\times$5-R1/4 |

|||

E-KYT-4$\times$6 | 4$\times$6 | E-FTS-4$\times$6-R1/4 |

|||

E-KYT-5$\times$7 | 5$\times$7 | E-FTS-5$\times$7-R1/4 | 0 - 0.15 |

||

E-KYT-6$\times$8 | 6$\times$8 | E-FTS-6$\times$8-R1/4 |

|||

E-KYT-6$\times$9 | 6$\times$9 | E-FTS-6$\times$9-R1/4 | 0 - 0.2 |

||

E-KYT-8$\times$12 | 8$\times$12 | E-FTS-8$\times$12-R3/8 | 0 - 0.15 |

||

*(A) Working pressure of E-SJUS-4$\times$6/E-SJUS-4$\times$6-BK (20$^\circ$C) is 0 - 0.4 MPa.

*(B) Working pressure of E-SJUS-6$\times$8/E-SJUS-6$\times$8-BK (20$^\circ$C) is 0 - 0.3 MPa.

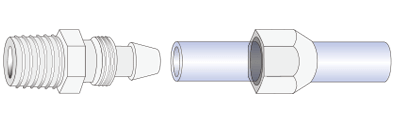

How to Assemble Fittings for Multi-Layer Tubing

(A) Cut the tubing in a perpendicular way. Pass a nut through the tubing.

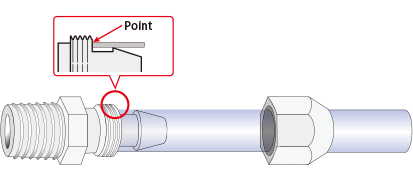

(B) Insert the nipple to the tubing. Make sure to insert to the end. There should be no gap between tubing and fittings.

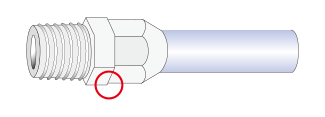

(C) Tighten the nut by wrench until there is no gap between the fitting body and the fitting nut.

Assembly Done !