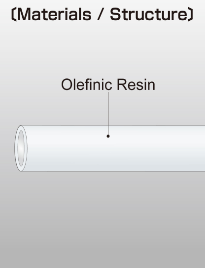

Pump Tubing (Olefin Type) [Model Number: POL]

Tubing for Peristaltic Pump Applications | High Chemical Resistance, High Durability, Very Soft and Flexible Tube | Better Chemical Resistance than a Silicone Tubing | Two Types Available (Normal Olefin Type and Higher Grade of Olefin Type)

Fluids

chemicals

chemicals ink

ink water

water Applications

- For Industrial Ink-Jet Printers (For Pump Applications)

- For Transferring Inks (For Ink-Supply Pipe & Waste Ink Line)

- For Transferring Detergent Solution for Dishwasher

- For Chemical Piping such as Acid and Alkali

- For Transferring Fluids (at a Fixed Quantity)

Functions

Non-PVC

Non-Adhesiveness

Chemical Resistance

Low Elution

Low Odor

Flexibility

Non-Phthalic Acid

RoHS 2 Free

Characteristics

- Flexibility...Like PVC tubing, POL shows higher levels of flexibility. This greatly improves work efficiency, which places in a confined space.

- Work Efficiency...Because of the softness of the tubing, the insertion to the fittings is easy.

- High Durability...In the pump endurance test, no crack or fracture has found. (For more information, please refer to "Technical Information" at the bottom of this webpage.)

- Plasticizer-Free...POL does not contain plasticizer (an elution material) at all. POL is an oil-free tubing.

- Low Elution and Low Odor...Compared with a PVC tubing, the levels of elution and smell are lower.

- Chemical Resistance...Since POL is used for waste ink line, which shows moderate chemical resistance.

- RoHS Compliant...POL is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that POL does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.)

- Positive List (PL) Compliance...POL Type B (Higher Grade of Olefin Type) is compliant in the Positive List System (PL System), stipulated in the “Act for Partial Revision of the Food Sanitation Act” (Effective on June 1, 2020).

Product Standard

Type A: Made-to-Order Size (Example)

- Color : Milky White or Black

Type B: Made-to-Order Size (Example)

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please contact us and request the sample.

*Please note that Type A and Type B are made-to-order products. Please consult with us about the MOQ.

*Type B is an olefin tubing that improves the features of chemical resistance, weather resistance, heat resistance and outer layer smoothness. Please check these features with our product sample.

*If you are interested in this product and other offers (such as Cleanroom Packing Type), please fill out the following form. (Please note that we can also produce a size that is not listed on the table above.)

Made-to-Order Inquiry Form

■Chemical Resistance Data

| Base | Chemical Name | Olefin Elastomer

| Styrene Elastomer |

| Acid | Hydrochloric Acid (35%) | $\bigcirc$ | $\times$ |

| Hydrochloric Acid (98%) | $\bigcirc$ | $\times$ |

| Nitric Acid | $\bigcirc$ | $\times$ |

| Alkali | Caustic Soda (20%) | $\bigcirc$ | $\bigcirc$ |

| Sodium Hypochlorite | $\bigcirc$ | $\bigcirc$ |

| Inorganic Chemical | Bromine | $\times$ | - |

| Water | $\bigcirc$ | $\bigcirc$ |

| Ether/Ketone | Acetone | $\triangle$ | $\times$ |

| Methyl Ethyl Ketone (MEK) | $\triangle$ | $\times$ |

| Diethyl Ether | - | $\times$ |

| Tetrahydrofuran | $\times$ | $\times$ |

| Alcohol | Methyl Alcohol | $\bigcirc$ | $\bigcirc$ |

| Ethyl Alcohol | $\bigcirc$ | $\bigcirc$ |

| Isopropyl Alcohol | $\bigcirc$ | $\bigcirc$ |

| Oil | Kerosene | $\times$ | $\times$ |

| ASTM No.3 | $\times$ | - |

| Gasoline | - | $\times$ |

| Ink-Related Solvents | Acrylic Acid Ester | $\triangle$ | - |

| Glycerol | $\bigcirc$ | - |

| Diethylene Glycol | $\bigcirc$ | - |

| Ethylene Glycol | $\bigcirc$ | - |

| Diethylene Glycol Diethyl Ether | $\triangle$ | - |

| Aromatic | Toluene | $\times$ | $\triangle$ |

| Xylene | $\times$ | $\triangle$ |

| Aliphatic | N-Hexane | $\times$ | $\times$ |

| Cyclohexane | $\times$ | $\times$ |

| Carboxylic Acid | Acetic Acid (10%) | $\bigcirc$ | $\times$ |

| Ethyl Acetate | $\triangle$ | $\times$ |

$\bigcirc$: Can be used without any influence, or almost no influence on material.

$\triangle$: Can be used though having an influence on material to some extent.

Additional check before in use is required.

$\times$: Cannot be used.

- : No Data

Cautions:

Please note that we do not have our original fittings for this product. Please use the joints to seal an inner surface of the tube. If you inform us of the fittings you are going to apply with this product, we might be able to check the matching between the tubing and the fittings. Please fill out the following form for more detail.

Technical Information

Notes:

*1: Material Hardness is just for your reference.

*2: This indicates the compliance with the Positive List System (PL system) stipulated in the "Act for Partial Revision of the Food Sanitation Act" (Effective on June 1, 2020).

*3: This indicates whether or not the material is compliant in the FDA (U.S. Food and Drug Administration).

*4: Durability Test Conditions: Fluid: Water, Rotating Speed: 60 rpm, Tubing Size: I.D. 4mm x O.D. 6mm, Result: No Tear or Crack Found