Flexible Fluorine (ETFE) Resin Tubing (PVC Type) [Model Number: E-SJV]

Multi-Purpose | Chemical Resistant Soft Tube | Single-layer Teflon tubing is hard and easy to break. Our Flexible Fluorine (ETFE) Resin Tubing (PVC Type) [E-SJV] is an alternative tubing for a Teflon tubing. E-SJV is much softer than our standard E-SJ. Thus, if you feel E-SJ is a bit stiff, E-SJV is a solution for you.

Fluids

chemicals

chemicals ink

ink paint

paint flux

flux food

food drink

drink alcohol

alcohol oil

oil water

water powder

powder Applications

- For Painting Equipment, Organic Solvents for Printers and Paints

- For Transferring Chemicals of Laboratory Equipment

- For Transferring Fluids (such as Chlorine, Ozone, Nitrogen, Mercury and Methane) of Gas Chromatograph

- For Transferring Chemicals of Semiconductor-Related Equipment (Wet Bench) and Flat Panel Display (FPD) Manufacturing Devices

- For Transferring Beverage and Food

- For Transferring Alcohol, Cosmetics and Chemicals

- For Filling Lines of Paints and Adhesives

- For Filling Lines of Aroma, Additives and Coloring

- For Transferring Chemical Wastes

Functions

Solvent Resistance

Non-Adhesiveness

Chemical Resistance

Low Elution

Low Odor

Food-Sanitation

Flexibility

Transparency

Oil-Proof

Cold Resistance

Alcohol Resistance

Characteristics

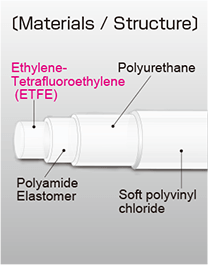

- Chemical Resistance...Since the inner layer is made of ETFE fluorine resin, E-SJV is resistant to most of the chemical substances. For more information, please refer to chemical resistance data.

- Flexibility...Due to the laminated structure, compared with a single-layer fluorine tubing, E-SJV is superior in flexibility. This improves your work efficiency.

- Hard to Break...Unlike a single-layer fluorine tubing, E-SJV is hard to break. (Even if it breaks, you can restore its shape to some extent.)

- Higher Non-Adhesiveness...Since ETFE fluorine resin is superior in terms of water-proof, you can wash out the fluids very easily.

- Easy to Cut...Since we print the cut mark on the hose every meter, it is easy to cut the length you would like to.

- Transparency...E-SJV enables you to check the fluid very easily.

- Original Fittings...By using our original fittings, you can avoid accidents which are caused by incorrect choices of hose and fittings. For more information on our original fittings, please scroll down to the end.

Certificates and Regulations

- RoHS Compliant...E-SJV is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that E-SJV does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.) Certificate is available on request.

- Food Sanitation Act Compliant...E-SJV conforms to the Food Sanitation Act No.380 (No.380 of the Ministry of Health and Welfare for Food Sanitation) (Conformity to N-Heptane) and the Food Sanitation Act No.324 (Positive List System) [No.324 of the Ministry of Health, Labour, and Welfare]. Regarding the conformity of the Food Sanitation Act No.324 (Positive List System), please download the certificate.

- Non-Use of UV-328...E-SJV does not contain UV-328. Certificate is available on request.

- Regulation (EC) No 1935/2004 and (EU) No 10/2011...An inner layer of E-SJV is compliant with (EC) No 1935/2004 and (EU) No 10/2011.

- Compliance with ADI/TSE/BSE Free...An inner layer of E-SJV does not contain ADI, TSE, and BSE.

Packing Images

Product Standard

Made-to-Order Size Example

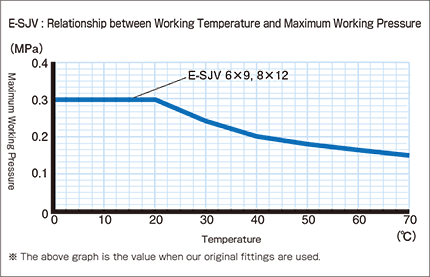

- Temperature Range : 0 - 70 $^\circ$C (32$^\circ$F - 158$^\circ$F)

- Color : Clear

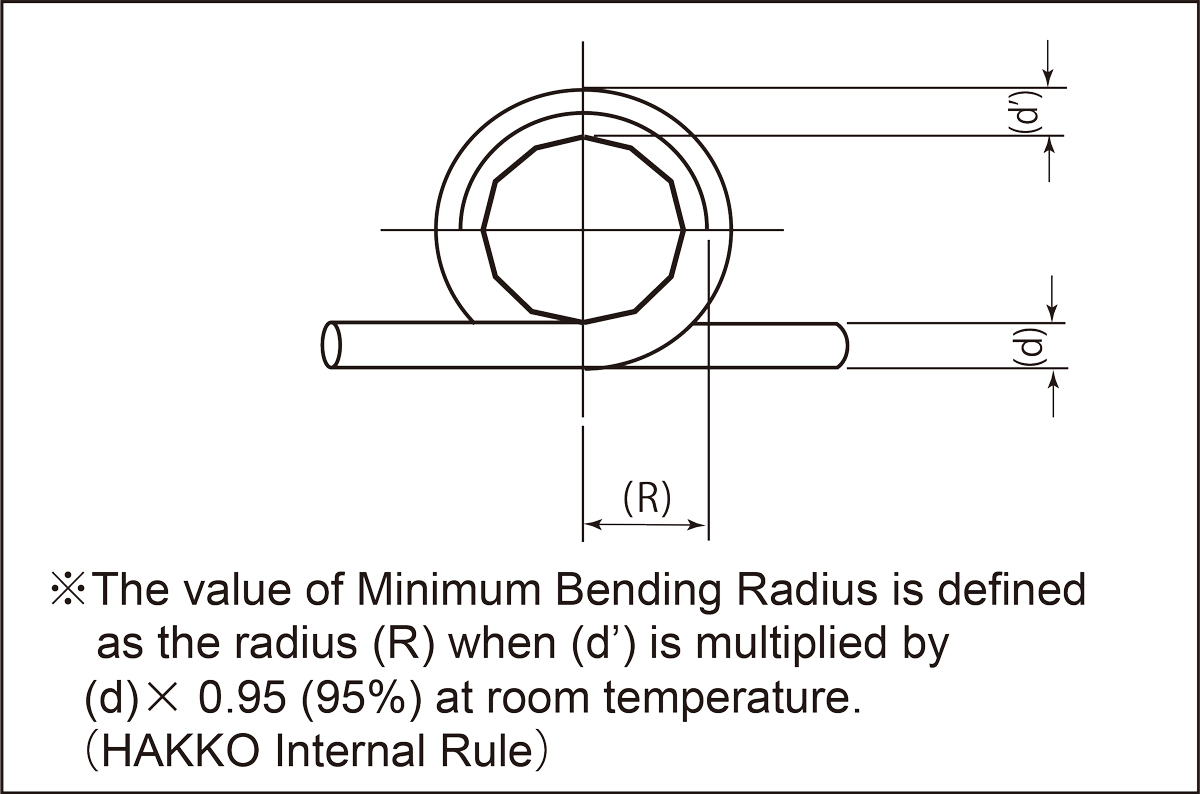

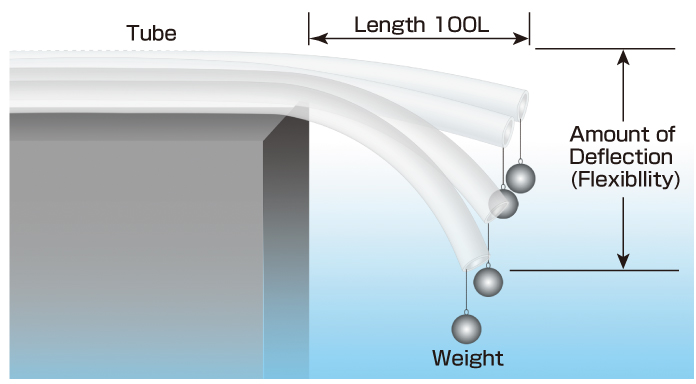

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please refer to the value of "Amount of Deflection" in the section of Technical Information or request the sample.

*If you are interested in Made-to-Order size, please fill out the following form.

Made-to-Order Inquiry Form

Leaflet Request

For more information on our Product Standard of E-SJV, please click "Product Leaflet Download" above.

Specification Request

For more technical information (such as Thickness of Each Layer and Precautions in Use) on E-SJV, please click "Product Specification Download" above.

Cautions:

- Due to the laminated structure tubing, please use the joints to seal an inner surface of the tubing.

- Please do not use the joints to seal an outer surface of the tubing. This may result in the bursting or coming off from the tubing.

- When you use our products, please refer to "Precautions for Use." ("The Precautions for Use" of E-SJV is also downloadable here.)

- In terms of chemical resistance, please refer to "Chemical Resistance Data."

- Although the inner layer is made of ETFE fluorine, please make sure whether or not E-SJV is usable for high purity fluids before you use.

- Although the inner layer is resistant to fluids, depending on working environments, the fluids would be permeated through the inner layer, resulting in the danger of swelling and degradation of the middle or outer layer.

Case Study

Problem: A Single-Layer Teflon Tube is hard and easy to break.

An analytical instrument manufacturer (called "Company A" hereinafter) was looking for a flexible tubing for better handling and easy installation. An inner layer should be made of fluorine, and its bending radius is smaller and hard to break. Company A is also concerned about the chemical resistance of polyurethane resin (outer layer) against the gases that fill the equipment inside.

HAKKO Solution:

HAKKO proposed E-SJV: Flexible Fluorine (ETFE) Resin Tubing (PVC Type) and provided a sample. The inner layer of E-SJV shows a feature of smoothness and higher levels of chemical resistance. The outer layer is made of PVC, which makes the tubing softer and more flexible. Besides, PVC shows better resistance against acid and alkali than polyurethane. As a result, compared with a teflon tubing, E-SJV is flexible, hard to break and restore its shape even if it kinks. After Company A evaluates our E-SJV, E-SJV passed the criteria of smoothness, chemical resistance (both inner and outer layers) and flexibility.

Technical Information

(A) Relationship Graph between Working Temperature and Maximum Working Pressure

(B) Flexibility Comparative Data

*Test Temperature: 20$^\circ$C (68$^\circ$F)

Results: "Amount of Deflection" is one indication of flexibility. Flexibility varies depending on hose (tubing). The larger the amount of deflection is, the more flexible the hose (tubing) is. The lower the minimum bend radius value is, the harder the hose (tubing) is. Thus, E-SJV is much more flexible than E-SJ.

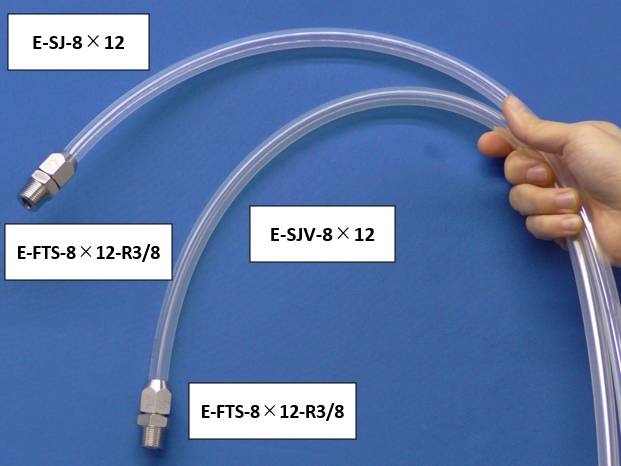

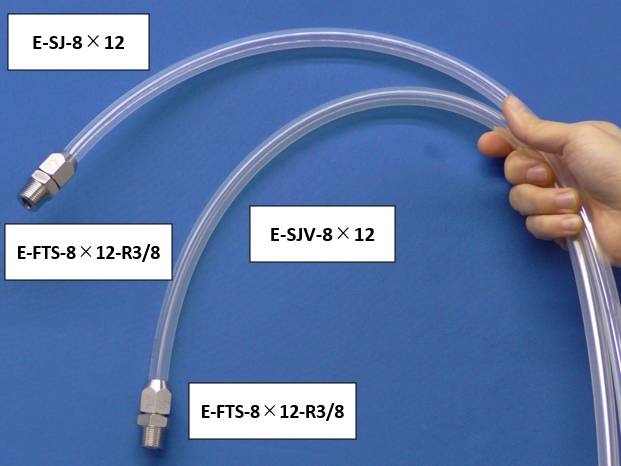

(C) Flexibility Difference Image (E-SJ vs. E-SJV)

HAKKO Original Fittings for E-SJV

| Product Name | Materials, Characteristics |

| Fittings for Multi-Layer Tubing [Model Number: E-FTS-F]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|

| Fittings for Multi-Layer Tubing (with Tubing Guide) [Model Number: E-FTS-GN]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|