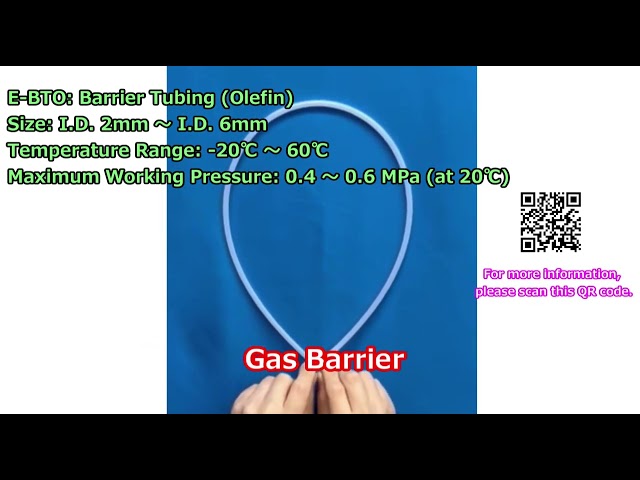

Barrier Tubing (Olefin) [Model Number: E-BTO]

For Roll-to-Roll, Textile, Ink-Jet Printers (For Non-Aggressive Inks) | High Barrier Tubing, De-Gas Tubing, Olefin Tubing | Keep high levels of Dissolved Oxygen

Fluids

ink

ink Applications

- For Wide-Format, Textile, Roll-to-Roll Ink-Jet Printers

- For Water-Based Inks (and Non-Aggressive Inks)

- For Edible Inks

Functions

Non-PVC

Chemical Resistance

Food-Sanitation

Flexibility

Ink Resistance

Oxygen Barrier

Characteristics

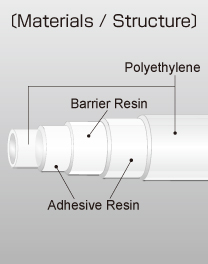

- Ink Resistance...Since inner and outer layers are made of polyethylene resin, E-BTO shows resistance against water-based ink.

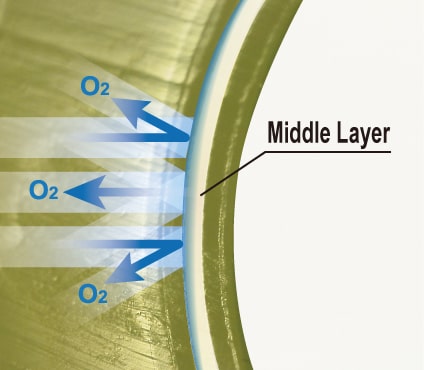

- High Gas Barrier...Since the middle layer is composed of barrier resin, the value of dissolved oxygen remains low.

- Flexibility...Due to the laminated structure, compared with a single-layer tubing, E-BTO is superior in flexibility. This improves your work efficiency.

- Plasticizer-Free...E-BTO does not contain plasticizer at all, so you do not have to worry about the elution to the ink.

- Non-PVC...E-BTO is made of non-PVC material.

- Transparency...E-BTO enables you to check the fluid very easily.

Certificates and Regulations

- RoHS Compliant...E-BTO is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant products mean that they do not contain or below the threshold of 10 substances.) Certificate is available on request.

- EU REACH and UK REACH...E-BTO is compliant with REACH SVHC 31st list (242 substances). Certificate is available on request.

- Food Sanitation Act Compliant...E-BTO conforms to the Food Sanitation Act No.380 (No.380 of the Ministry of Health and Welfare for Food Sanitation) (Conformity to N-Heptane) and the Food Sanitation Act No.324 (Positive List System) [No.324 of the Ministry of Health, Labour, and Welfare]. Regarding the conformity of the Food Sanitation Act No.324 (Positive List System), please download the certificate.

- PFOA and PFOS...E-BTO does not contain perfluorocarboxylic acids (PFCAs C 9 – C 14), their salts or PFCA-related substances.

- PFAS...E-BTO does not exceed the threshold of PFAS.

- Non-Use of UV-328...E-BTO does not contain UV-328. Certificate is available on request.

Packing and Product Images

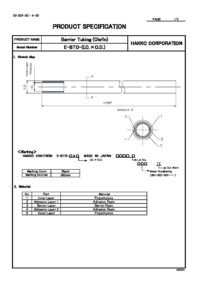

Product Standard

- Temperature Range : -20 - 60 $^\circ$C (-4$^\circ$F - 140$^\circ$F)

- Color : Clear

- One Roll Length: 20m and 100m

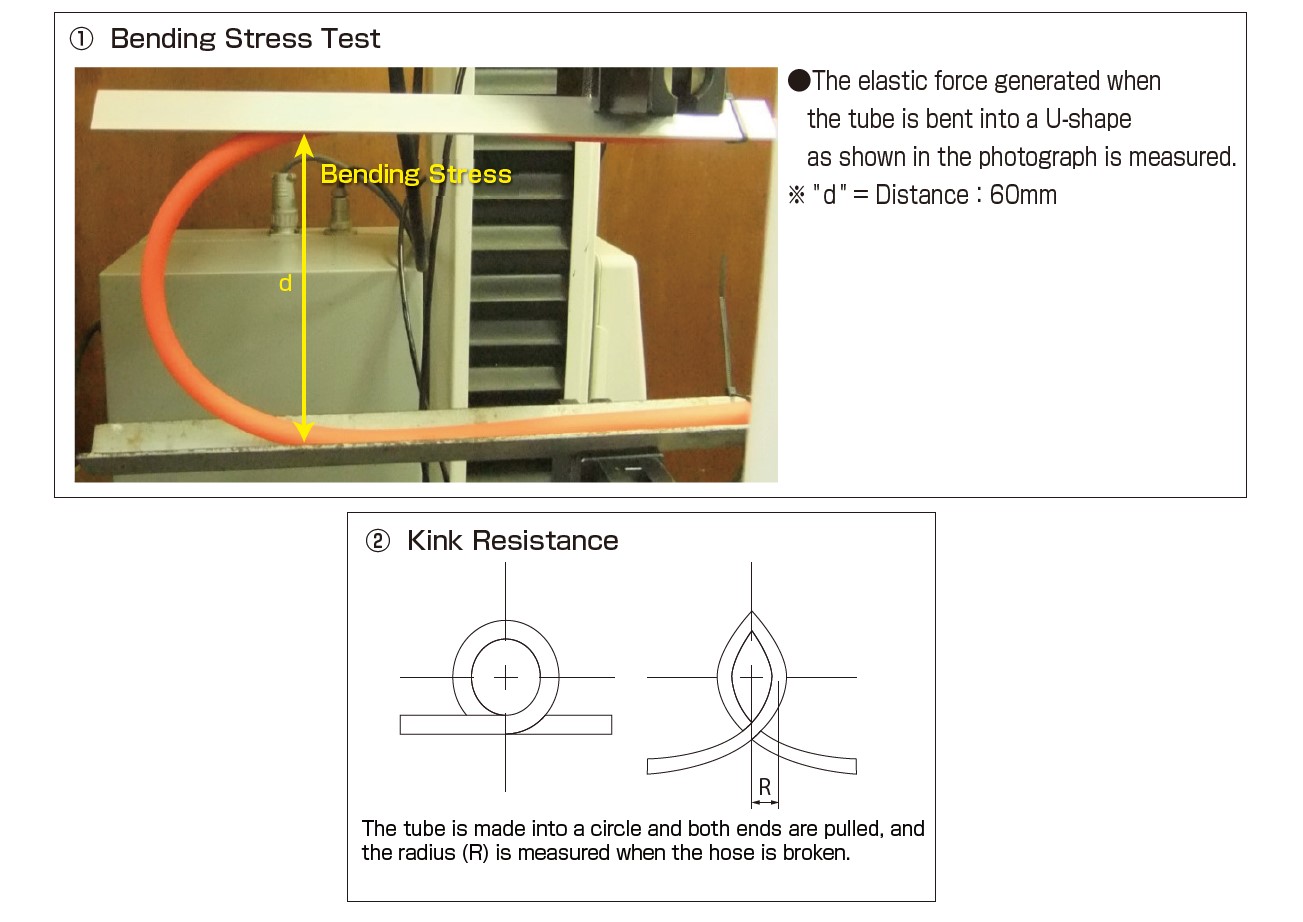

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please refer to the value of "Bending Stress Data" in the section of Technical Information or request the sample.

*If you request an olefin barrier tubing with a non-standard size or an olefin barrier tubing for UV-curable inks, we can offer as a made-to-order product. Please fill out a Made-to-Order Inquiry form below.

Made-to-Order Inquiry Form

Leaflet Request

For more information on our Product Standard of E-BTO, please click "Product Leaflet Download" above.

Specification Request

For more technical information (such as Thickness of Each Layer and Precautions in Use) on E-BTO, please click "Product Specification Download" above.

Point:

What is a Barrier Tube? Reasons for the Need for Tubes with Excellent Oxygen Barrier

If the oxygen barrier or water vapor barrier is low for the ink supply tube, oxygen and water vapor in the atmosphere permeate into the ink.

This leads to the clogging of print head or ink discharge defect due to the generation of air bubble.

Also, if the low oxygen barrier or water vapor barrier tube is used, solvent components of the ink inside the tube will evaporate, changing the ink quality. Printing quality badly affects.

This HAKKO five-layer product includes the barrier resin (middle layer), keeping the oxygen less likely to be permeated.

Cautions:

- The material of the middle layer and outer layer is inferior in chemical resistance to the inner layer. Do not allow chemicals to adhere to the tube during immersion or fitting insertion as it may cause swelling and cracking of the tube.

- When using the metal fittings, do not use any scratches or rusty fittings on the nipple surface. Damage to the inside of the tube may cause tube rupture or leakage. Also, do not use resin fittings with scratches on the surface of nipples. Depending on the state of the junction (parting line) of the resin joint, fluid may leak. Please confirm the matching between E-BTO tubing and the fittings. If you need our technical support in fittings, please fill out this form.

- Due to the laminated structure tubing, please use the joints to seal an inner surface of the tubing.

- Please do not use the joints to seal an outer surface of the tubing. This may result in the bursting or coming off from the tubing.

- When you use our products, please refer to "Precautions for Use." ("The Precautions for Use" of E-BTO is also downloadable here.)

- In terms of chemical resistance, please refer to "Chemical Resistance Chart on Polyethylene."

Technical Information

(A) Slide Curvature Test (5 million times)

(B) Gas Barrier Test Data

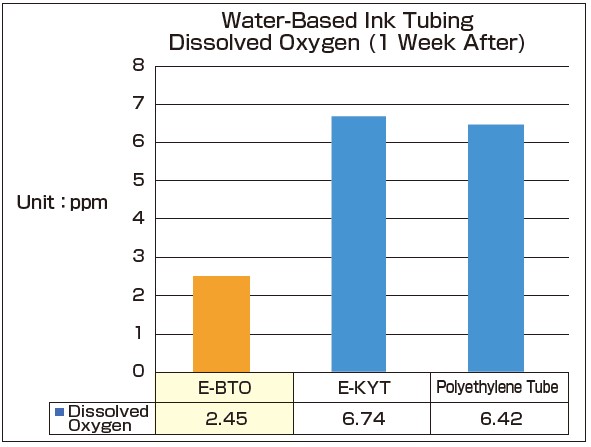

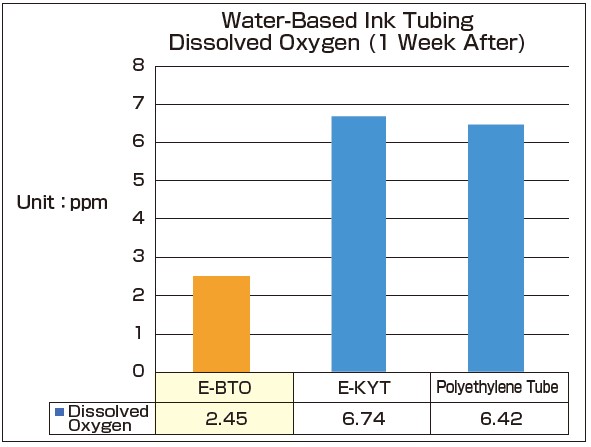

1. Gas Barrier Test

Seal the de-gas water into the tubing. Then, leave the tubing under the conditions of temperature (20 $^\circ$C [68 F]) and humidity (50%) for 1 week. Then, check the increasing amount of dissolved oxygen for each tubing.

2. Sample

Olefin-Based (for Water-Based Ink) Tubing

- E-BTO-4$\times$6 Barrier Tubing (Olefin)

- E-KYT-4$\times$6 KY TUBE

- Polyethylene Tube (4mm$\times$6mm)

3. Results

Result: E-BTO is superior to E-KYT and polyethylene tube in terms of gas barrier feature.

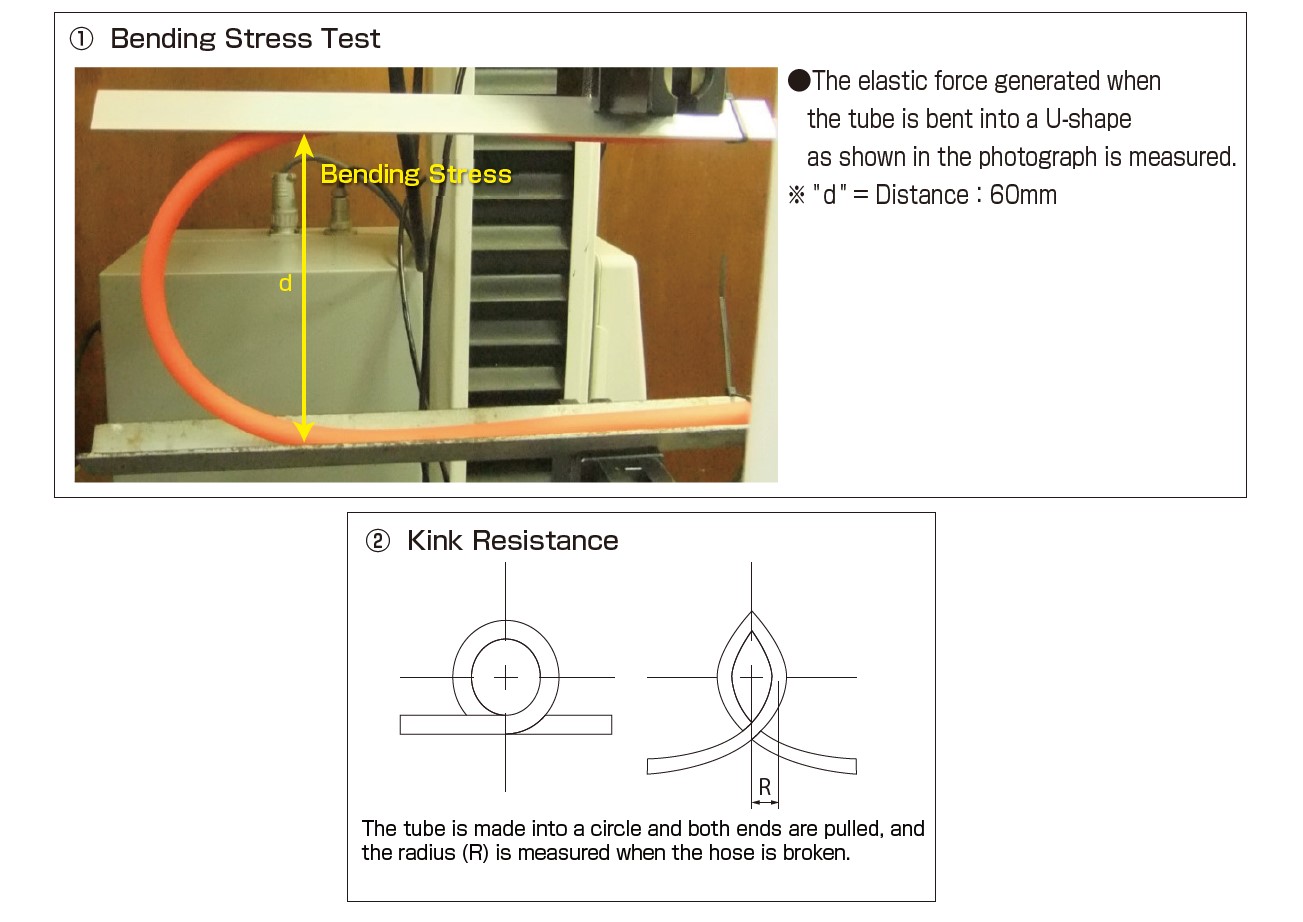

(C) Flexibility Test Data

1. Test Methods

2. Results

Compared with the polyethylene tubing manufactured by other corporation, HAKKO E-BTO shows a smaller bending stress, meaning that E-BTO is more flexible.

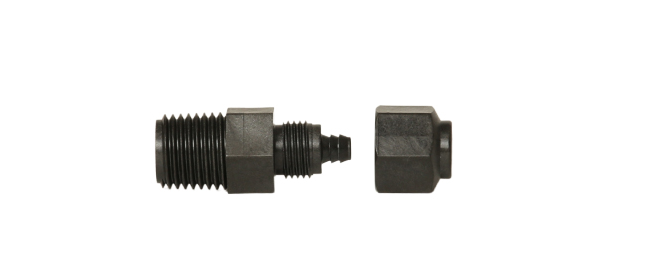

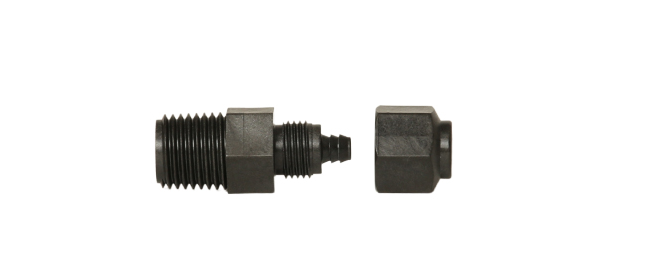

HAKKO Original Fittings for E-BTO

| Product Name | Materials, Characteristics |

| Fittings for Multi-Layer Tubing [Model Number: E-FTS-F]] |

- Material: SUS316L (SS316L) (Body) and SUS304 (SS304) (Nut)

- It is designed by HAKKO tubing products, so you do not have to worry about fluid leakages and coming off.

- Specify temperature range and working pressure for each product.

- It is excellent in corrosion resistance [Body: SUS316L (SS316L)].

- Since it is made of stainless steel (Passivation Treatment), you can transfer a wide variety of fluids.

|

|

| PEEK (Carbon Reinforced) Nut Type Fittings [Model Number: AL]] |

- Material: PEEK

- Lightweight...Fitting weight is less than one-fifth, compared to same-size SUS joints, leading to overall weight reduction of equipment.

- Great Heat Resistance...PEEK material has excellent heat resistance among resins.

- Chemical Resistance...PEEK material has excellent resistance to a wide range of chemicals including acids, alkalis and organic solvents.

- Mechanical Strength...Carbon fiber is added to the engineering plastic of PEEK, which is strong in tensile and impact resistance.

|

|