Chemical Resistant Hose/Tubing

Users transfer chemicals in their various kinds of applications, but in some cases, they are not sure whether or not the hose or tubing is suitable for their applications. Chemical resistance greatly varies, depending on the hose or tubing material.

If the hose or tubing is deteriorated in a short period of time, such as hardening, swelling or discoloration, it is time to review the hose/tubing and choose one with better chemical resistance. The frequency of hose/tubing change will decrease if the hose/tubing that is suitable for fluids (chemical solutions) is chosen.

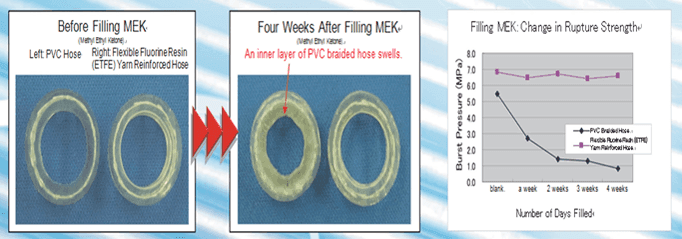

The below image is one example of incorrect choice of hose, as the image shows before and after MEK (Methyl Ethyl Ketone) is transferred.

Above the image, you can easily find that a hose without enough chemical resistance is damaged so quickly.

For your information, frequently used chemical names are as follows:

(A) Thinner

(B) Adhesives

(C) Solvents (MEK)

(D) Sodium Hypochlorite

(E) Sodium Hydroxide

(F) Benzene

(G) Surface Coating Liquid, Drum Coating Liquid

(H) Substrate Treatment Liquid

(I) Ethylene Glycol (Coolant Liquid)

(J) N-Methyl-2-Pyrrolidone (NMP)

We can offer the suitable product for the above chemical names. When you check the chemical resistance of our products, please refer to the chemical resistance data.

If the chemicals used may be the name of the product or the mixture, and may not be listed in our chemical resistance data, please contact us from below. We can also provide a product sample for your chemical inclusion test.

Case Study

Current Problem: Company A has been using a PVC hose for transferring water-based paints. However, due to the low chemical resistance, they have to replace into a new hose frequently, which reduces the efficiency of production and increases the industrial waste.

HAKKO Solutions: Flexible Fluorine (ETFE) Resin SUS Spring Wire Hose [Model Number: E-SJSP]

Since Company A requests a hose with high stability and high chemical resistance against water-based paints, we offer E-SJSP. Company A is satisfied with a situation that the efficiency of production greatly improves.

20220810.jpg)