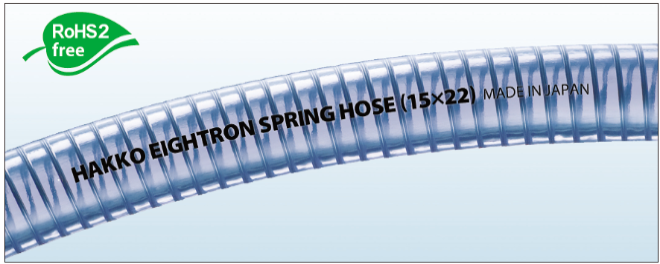

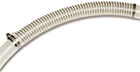

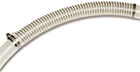

SPRING HOSE [Model Number: E-SP]

Industrial PVC Hose | Metal Steel Wire Hose; Difficult to break under the Space-Saving Piping

Fluids

chemicals

chemicals oil

oil water

water air

air Applications

- For Transferring Air, Water, Oil and Chemicals at Machine Tools, Molding Machines and Industrial Equipment

- For Space-saving Piping, preventing from Kinking

- For Maintaining Stability of the Shape

- For Temporary Pipes at Engineering Works and Construction Sites

- For Protection of Thin Rods such as Pipes

Functions

Flexibility

Vacuum

Transparency

Hard to Break

Characteristics

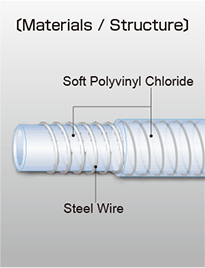

- Bending...Steel wire makes it difficult to be crushed or kinked, leading to high stability in its shape.

- Vacuum...E-SP stands proof against negative pressure (can be used in vacuum conditions).

- Transparency...E-SP (clear blue color) enables you to check the fluid very easily.

- Made-In-Japan High-Quality Hose...E-SP is made in Japan, a high-quality spring hose.

- Original Fittings...By using our original fittings, you can avoid accidents which are caused by incorrect choices of hose and fittings. For more information on our original fittings, please scroll down to the end.

- Flat Structure...The inner layer of the hose is flat, which is less likely to accumulate the fluids.

Certificates and Regulations

- RoHS Compliant...E-SP is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that E-SP does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.) Certificate is available on request.

- Non-Use of UV-328...E-SP does not contain UV-328. Certificate is available on request.

- TSCA (Toxic Substance Control Act) Compliance...E-SP does not use decaBDE, PIP(3:1), 2,4,6-TTBT, PCTP and HCBD. Certificate is available on request.

Packing Images

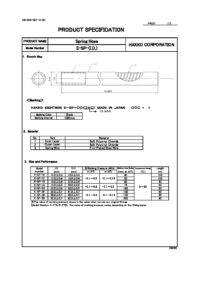

Product Standard

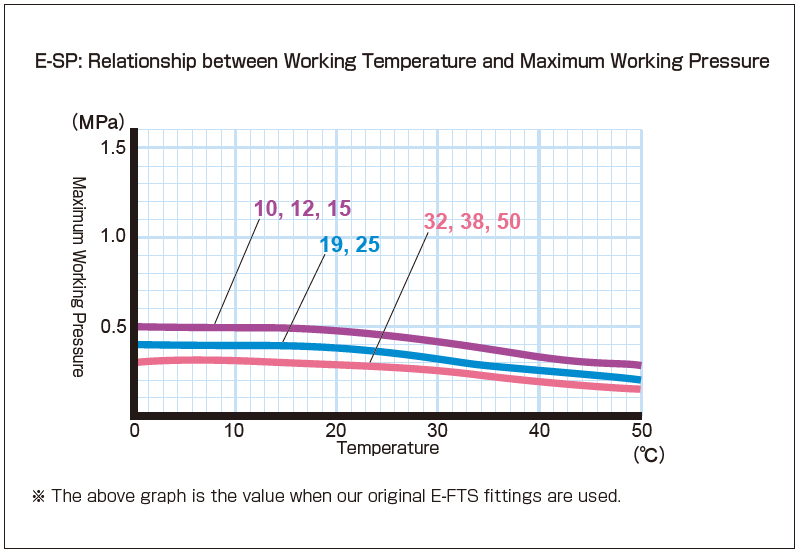

- Temperature Range : 0 - 50 $^\circ$C

- Color : Clear Blue

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please contact us and request the sample.

Leaflet Request

For more information on our Product Standard of E-SP, please click "Product Leaflet Download" above.

Specification Request

For more technical information (such as Thickness of Each Layer and Precautions in Use) on E-SP, please click "Product Specification Download" above.

Cautions:

- Due to the spring hose, please use the joints to seal an inner surface of the hose.

- Please do not use the joints to seal an outer surface of the hose. This may result in the bursting or coming off from the hose.

- When you cut the spring wire, be careful not to get hurt on your hands, because the spring wire may stick out at the cross-section of the hose.

- When the spring wire sticks out, cut it off neatly with a nipper. For visual images of how to cut the spring hose, please click here.

- In case the spring wire is broken, it is impossible to restore its shape. Please replace into a new hose.

- E-SP does not have the features of oil-proofness. Depending on the using conditions, hose may harden if you transfer oil.

- When you use our products, please refer to "Precautions for Use." ("The Precautions for Use" of E-SP is also downloadable here.)

- In terms of chemical resistance, please refer to "Chemical Resistance Data."

Frequently Asked Questions

Question: In terms of working pressure, which is higher either E-TB or E-SP?

Answer: Some might think that in terms of working pressure, E-SP is higher, because the steel wire is included in the hose. However, the steel wire is intended for vacuum resistance. For positive working pressure, E-TB is higher than E-SP. For more information on working pressure for each size, please refer to the product pages of E-TB and E-SP.

Question: We would like to know how to cut E-SP correctly.

Answer: Please watch this short video clip available on our YouTube Channel.

Technical Information

(A) Relationship between Working Temperature and Maximum Working Pressure

HAKKO Original Fittings for E-SP

| Product Name | Materials, Characteristics |

| EIGHTNIPPLE S Fittings [Model Number: E-FTS]] |

- Material: SUS316L (SS316L)

- SUS316L (SS316L) is superior in corrosion resistance, so you can transfer a wide range of fluids.

- Two-stage flat nipple structure which maximizes hose pressure

- Our Original Barb Nipple Fittings

- Made-in-Japan Fittings

|

|

| EIGHTNIPPLE B Fittings [Model Number: E-FTB]] |

- Material: BSBM (Brass)

- Compliant with RoHS2 requirement

- Two-stage flat nipple structure which maximizes hose pressure

- Our Original Barb Nipple Fittings

- Made-in-Japan Fittings

|

|

Cautions:

- For EIGHTNIPPLE S and B Fittings, please fasten with two hose clamps.

HAKKO Original Accessory for E-SP

| Product Name | Materials, Characteristics |

| Protective Spring Guards [Model Number: E-HSL]] |

- Material: SUS304 (Band, Spring and Fastener)

- Spring guards prevent kinking, so you can transfer fluids safely.

- E-HSL prevents kinking even if the bending radius is small due to the space-saving piping.

- When you install E-HSL on the fitting, E-HSL can be used as an alternative to flat band.

|

|