Tube/Hose for Analytical Equipment (Analysis Instrumentation) and Water Treatment

Introduction

Depending on what kinds of fluids you will analyze, you need to use a different type of analytical equipment. Even the equipment for gas chromatograph (HPLC), various kinds of gas (such as oxygen, nitrogen, chlorine, methane, ozone, noble gas, carbon dioxide gas, sulfur, nitrogen dioxide, sulfur dioxide, hydrogen sulfide and phenol) are the objects for measuring (gas analyzer and gas detector). When you analyze the components of the fluids, the elemental analysis equipment is used for the analysis of water (water sampler), lubricant oil, coolant oil and mercury. A particle counter, measuring dusts and impurities, is often used in the cleanroom. Thus, depending on the fluids, various requirements to the tubing/hose exist. HAKKO can offer various products to meet these requirements.

Tube/Hose Selection for Each Application

(A) For Biochemical and Component Analysis Equipment (Analysis Instrumentation)

When the component analysis test is conducted, of course, we expect the accurate results. In order to obtain the accurate results, the component (regardless of air, gas, particles and fluids) has to pass through a tubing (titrating tube) or a hose that has features of non-plasticizer, non-adhesiveness (smoothness), non-contamination, enough chemical resistance, high oxygen (gas) barrier, low elution and low odor. Otherwise, the test results might not be accurate.

Besides this, flexibility and the ease of handling are frequently requested, due to the compactness of the equipment. In this application, a single-layer fluorine tubing has been widely used for many years, but the end users are not satisfied with the stiffness (easy to kink) of single-layer fluorine tubing. Instead, HAKKO Flexible Fluorine (ETFE) Resin Hose Series have the following features: flexibility (kink resistance), great chemical resistance and transparency (easy to see through inside). HAKKO can also offer a barrier tubing (or hose) as a made-to-order product.

(B) For Analytical Equipment (Without Chemical Resistance Requirement)

Even if the tube/hose does not require chemical resistance, PVC tube or hose might distort the measurement results. In this case, HAKKO recommends Olefin-Based KY Hose Series, because Olefin-Based KY Hose Series do not contain any plasticizer, a source of elution from the tubing or hose.

(C) For Water Treatment

Water treatment process often requires the following corrosive fluids: Chlorine, Sodium Hypochlorite, Dilute Hydrochloric Acid and Sodium Hydroxide. For these kinds of fluids, due to the better chemical resistance of the styrene resin (the outer layer of Olefin-Based KY Hose Series) than polyurethane (the outer layer of Flexible Fluorine (ETFE) Resin Hose Series), HAKKO recommends Olefin-Based KY Hose Series.

Technical Information

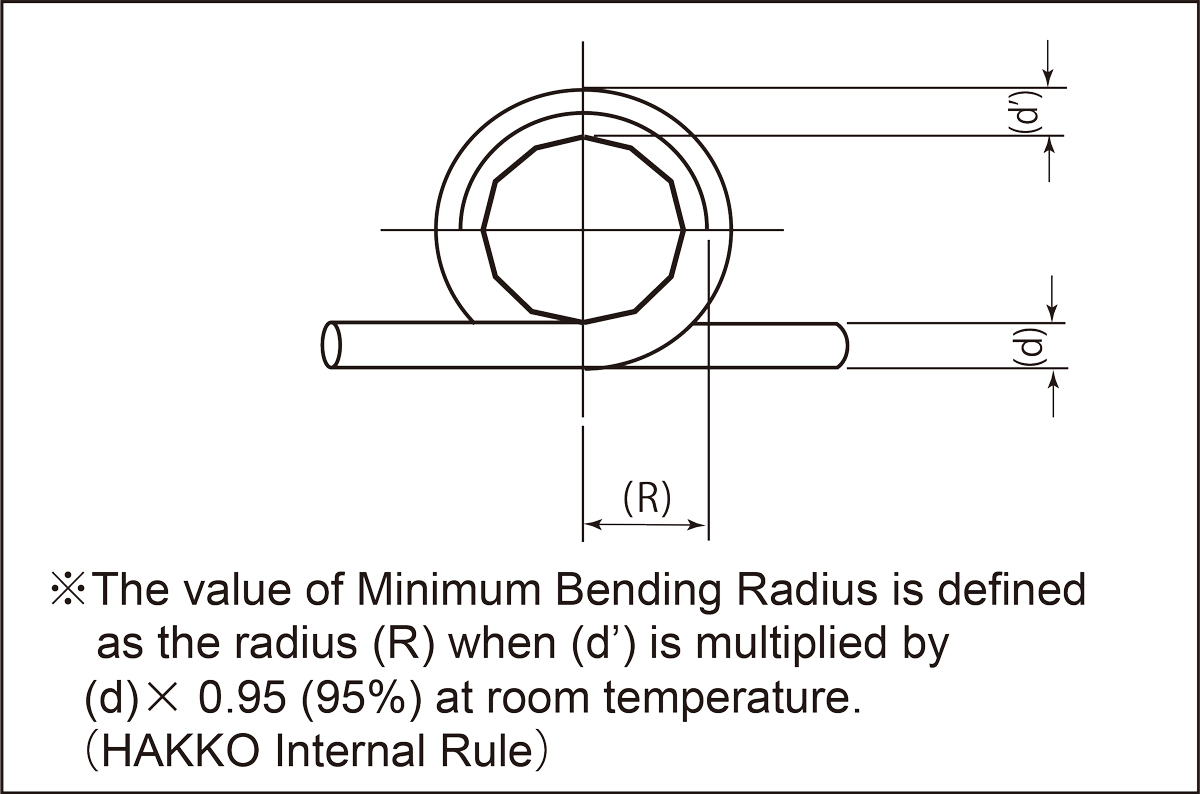

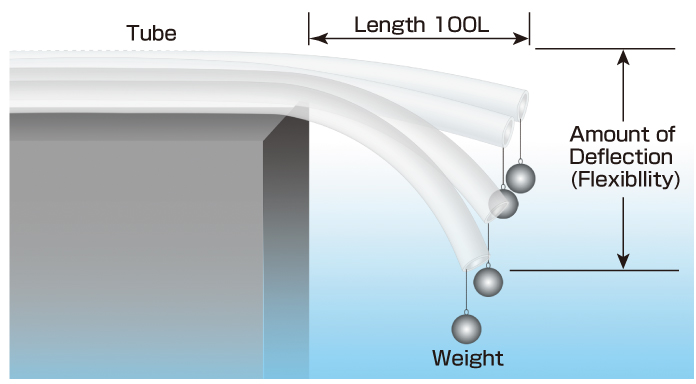

(A) Minimum Bend Radius and Amount of Deflection (Flexibility) Data

Test Sample | Minimum Bend Radius (mm) | Amount of Deflection (mm) |

|---|---|---|

| E-SJ-4$\times$6 | 23 (Catalog Value: 25) | 31 |

| E-SJUS-4$\times$6 | 50 | 50 |

| PTFE Tubing (4$\times$6) | 20 | 7 |

| PFA Tubing (4$\times$6) | 23 | 6 |

Test Sample | Minimum Bend Radius (mm) | Amount of Deflection (mm) |

E-SJV-6$\times$9 | 45 | 40 |

E-SJ-6$\times$9 | 35 | 17 |

E-SJV-8$\times$12 | 55 | 19 |

E-SJ-8$\times$12 | 50 | 8 |

Results: "Amount of Deflection" is one indication of flexibility. Flexibility varies depending on hose (tubing). The larger the amount of deflection is, the more flexible the hose (tubing) is. Thus, E-SJ and E-SJUS are much more flexible than PTFE and PFA tubing. E-SJV is more flexible than E-SJ.

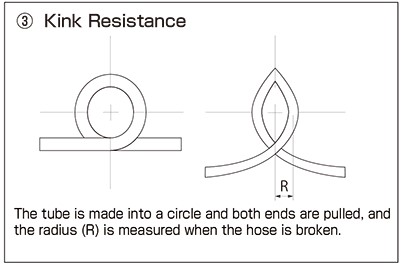

(B) Kink Resistance Data

Model Number | Kink Resistance Value (R) |

|---|---|

E-KYT-4×6 | 12.5mm |

E-SJ-4×6 & E-SJ-4×6-CBU & E-SJ-4×6-BK | 11mm |

E-SJUS-4×6 & E-SJUS-4×6-BK | 20mm |

(C) Leach Test Data

Item | E-KYT & E-KYS | PVC TUBE | POLYETHYLENE TUBE | Determination Limit |

|---|---|---|---|---|

Non-Ionic Surfactant | No Detection | 1 | No Detection | 0.005mg/L |

Phenol | 3 | 0.014mg/L | 0.0005mg/L |

|

Total Organic Carbon | 0.1 | No Detection | 0.3mg/L |

*Test Method: JIS S 3200-7: 2004 [Equipment for Water Supply Service]

Notes: Depending on the materials of the hose, plasticizer and stabilizer may elute. Data on the above show the levels of low elution of E-KYT and E-KYS. The results above are measured values are NOT guaranteed.

Standard Product Summary

Flexible Fluorine (ETFE) Resin Hose Series

Product Model Number | Standard Size Range (I.D.) | Product Color |

|---|---|---|

| E-SJ | 2mm - 9mm & 1/8" - 3/8" | Clear |

| E-SJECO | 4mm - 6mm | Clear |

| E-SJAST | 4mm - 8mm | Clear |

| E-SJ-BK | 2mm - 8mm & 1/8" - 1/4" | Black |

| E-SJ-CBU | 2mm - 8mm | Clear Blue |

| E-SJUS | 2mm - 8mm & 1/8" - 1/4" | Clear |

| E-SJV | 6mm - 8mm | Clear |

| E-SJB | 9mm - 38mm | Clear |

| E-SJSP | 12mm - 38mm | Clear |

Olefin-Based KY Hose Series

Product Model Number | Standard Size Range (I.D.) | Product Color |

|---|---|---|

| E-KYT | 2mm - 8mm & 1/4" | Natural |

| E-KYS | 6mm - 50mm | Natural |

Problem Solving

Problem 1: A Single-Layer Teflon Tube is hard and easy to break.

A gas analysis equipment manufacturer (called "Company A" hereinafter) sent an inquiry to us regarding tubing. Company A looked for a flexible tubing for better handling and easy installation. An inner layer should be made of fluorine whose bending radius is smaller and harder to break.

HAKKO Solution 1:

HAKKO CORPORATION proposed E-SJ: Flexible Fluorine (ETFE) Resin Tubing and provided a sample. E-SJ is made of three layers: the inner layer is made of ETFE fluorine, the middle layer is made of polyamide and the outer layer is made of polyurethane. The inner layer shows a feature of smoothness, and chemical resistance is almost the same as fluorine resin. Also, the outer layer is made of polyurethane, which makes the tubing softer and more flexible. As a result, compared with a Teflon tubing, E-SJ is flexible, hard to break and restore its shape even if it kinks. After Company A evaluates our E-SJ, E-SJ passed the criteria of smoothness, chemical resistance and flexibility.

Problem 2: PVC Hose becomes sticky and harder.

A sea water sampler equipment manufacturer (called "Company B" hereinafter) has been used a PVC hose. However, a PVC hose installed with the water sampler equipment becomes sticky and harder. Company B found that this phenomenon is caused by the elution of PVC materials, leading to the conclusion that the analysis results might not be accurate. Thus, Company B looked for a Non-PVC hose for less elution.

HAKKO Solution 2:

HAKKO CORPORATION proposed E-KYS: KY SUNFOODS HOSE and provided a sample. E-KYS is made of three layers: the inner layer is made of olefinic resin, the middle layer is made of styrene elastomer with reinforced yarn and the outer layer is made of styrene resin. E-KYS is made of non-PVC materials, and after their sampling testing, they found that E-KYS does not become sticky and harder, confirming that the elution level is low. Besides this, compared with E-SJB: Flexible Fluorine (ETFE) Resin Hose Yarn Reinforced Hose, E-KYS is more economical. As a result, Company B decided to adopt E-KYS.

*If you are interested in our Made-to-Order Offer (such as special size, color, cleanroom packing and anti-static offer), please fill out the following form.

20220810.jpg)