Tube for Ink-Jet Printers: Ink-Supply Tube

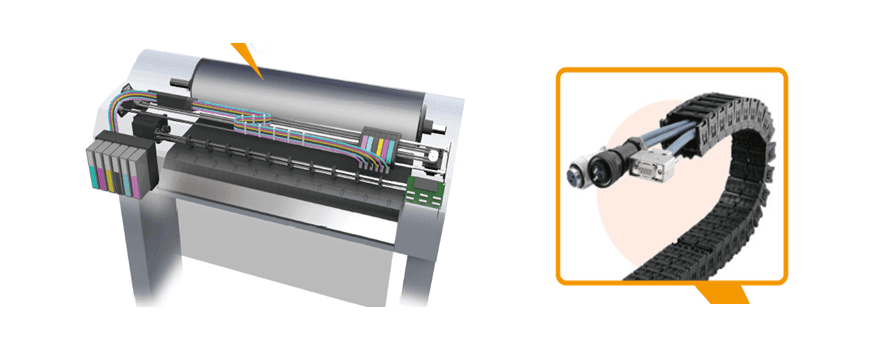

When you select a tube for ink-jet printers, a tube will be a key item. This is because inks will be transported through the tubing, and the quality of the tubing greatly affects the inks and printing quality. Also, due to the improving quality of wide-format, roll-to-roll, textile, ceramic tile and corrugated boards' ink-jet printers these days, there are so many kinds of inks (such as solvent-based inks, eco-solvent inks, latex inks, water-based inks, aqueous inks, UV inks, UV curable inks, EB [Electron Beam] curable inks, degassed inks and oil-based inks) for various printing applications. These days, ink-jet technologies have been applied to other fields (such as fabric printing, food printing, tile/ceramic printing, printed electronics [OLED], 3D printing, wall printing, printing on lithium-ion batteries and printing on circuit boards).

In order to meet these various applications and inks, a tube has to have a high solvent resistance, high oxygen (gas) barrier property, low moisture permeability, flexibility, outer layer smoothness (sliding property and abrasion resistance) and anti-flammability (flame retardancy). If a tube has a problem of gas barrier property and moisture permeability, oxygen and moisture will mix into the ink.

Thus, the quality of ink will change, leading to clogging into the printing heads or generating a bubble of the inks. As a result, ink droplet will not be stable, which means that ink-jet ejection failure will occur. This badly affects the printing (output) quality. This problem also occurs when you do not run an inkjet printer for long periods of time. HAKKO CORPORATION offers various high-quality products for your applications, which meet various customers' needs.

If you would like to download a product leaflet for ink-jet printers, please download the leaflet above.

Our products are highly recommended for textile printers, wide-format ink-jet printers, large-format ink-jet printers, packaging printers, label printers, textile printers, dye sublimation printers, roll-to-roll printers, ceramics tile printers, bottle printers, garment printers (DTG), continuous feed printers, cut sheet printers, 3D printers (Sheet Lamination, Binder Jetting and Material Jetting Methods) and printheads.

Other than transporting inks through tube, we can offer an economical tube for waste-inks (for non-critical parts) and a tubing with PFAS-free material. (PFAS is the abbreviation of Per- and polyfluoroalkyl substances.) [Our stance on PFAS regulations and the information on PFAS-free product are available on this page.] Also, based on your request, we can manufacture a made-to-order product such as low VOC tube, ink tube for peristaltic pump, anti-flammable (flame retardancy: UL-Based Criteria [such as UL94]) tubing and tubing with cleanroom options.

We can offer multi-core tubing with/without layer-cutting and slit-cutting (up to 8 cores) as our made-to-order products. For more information on this, please click the following link: Multi-Core Tubing with Layer and Slit Cutting) and Multi-Core Tubing without Layer and Slit Cutting. If you are interested in our made-to-order products, please click the following button and fill out the form.

Product Selection Chart Based on the Ink Type

(A) Water-Based Ink

| Model Number | I.D Size | Flexibility | Gas Barrier | Solvent Barrier | Ink Resistance (Inner Layer) | Price |

| E-KYT | 2mm - 8mm & 1/4" | + | ||||

| E-PD | 2mm - 8mm | ++ | ||||

| E-SJ | 2mm - 9mm & 1/8" - 3/8" | +++ | ||||

| E-SJECO | 4mm - 6mm | ++++ | ||||

| E-SJUS | 2mm - 8mm & 1/8" - 1/4" | +++ | ||||

| E-SJV | 6mm - 8mm | +++ | ||||

| E-BTO | 2mm - 6mm | ++++ | ||||

| E-BTF | 2mm - 6mm | +++++ |

Flexibility: = Better = Best

Gas Barrier: = Better = Best

Solvent Barrier: = Yes $\times$ = No

Ink Resistance: = Better = Best

Price: Lowest (+); Highest (+++++)

Water Vapor Barrier: E-BTF is the highest.

(B) Solvent-Based Ink

| Model Number | I.D Size | Flexibility | Gas Barrier | Solvent Barrier | Ink Resistance (Inner Layer) | Price |

| E-SJ | 2mm - 9mm & 1/8" - 3/8" | + | ||||

| E-SJECO | 4mm - 6mm | ++ | ||||

| E-SJUS | 2mm - 8mm & 1/8" - 1/4" | + | ||||

| E-SJV | 6mm - 8mm | + | ||||

| E-BTF | 2mm - 6mm | +++ |

Flexibility: = Better = Best

Gas Barrier: = Better = Best

Solvent Barrier: = Yes $\times$ = No

Ink Resistance: = Better = Best

Price: Lowest (+); Highest (+++)

Water Vapor Barrier: E-BTF is the highest.

(C) UV-Based Ink

| Model Number | I.D Size | Flexibility | Gas Barrier | Solvent Barrier | Ink Resistance (Inner Layer) | Price |

| E-SJ-BK | 2mm - 8mm & 1/8" - 1/4" | + | ||||

| E-SJUS-BK | 2mm - 8mm & 1/8" - 1/4" | + | ||||

| E-BTF-BK | 2mm - 6mm | +++ |

Flexibility: = Better = Best

Gas Barrier: = Better = Best

Solvent Barrier: = Yes $\times$ = No

Ink Resistance: = Better = Best

Price: Lowest (+); Highest (+++)

Water Vapor Barrier: E-BTF-BK is the highest.

Chemical Resistance Data for Ink-Jet Product Series

| Chemical Name and Model Number | E-BTF | E-SJ/E-SJUS | E-PD | E-KYT | E-BTO | E-POL | NTU |

| Acrylic Acid Ester | $\bigcirc$ | $\bigcirc$ | $\triangle$ | $\triangle$ | $\triangle$ | $\triangle$ | $\triangle$ |

| Glycerol | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ |

| Diethylene Glycol | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ |

| Ethylene Glycol | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ | $\bigcirc$ |

| Diethylene Glycol Diethyl Ether | $\bigcirc$ | $\bigcirc$ | $\times$ | $\triangle$ | $\triangle$ | $\triangle$ | $\triangle$ |

| Acetone | $\bigcirc$ | $\bigcirc$ | $\times$ | $\bigcirc$ | $\triangle$ | $\triangle$ | $\bigcirc$ |

| MEK (Methyl Ethyl Ketone) | $\bigcirc$ | $\bigcirc$ | $\times$ | $\triangle$ | $\triangle$ | $\triangle$ | $\bigcirc$ |

$\bigcirc$: Can be used without any influence, or almost no influence on material.

$\triangle$: Can be used though having an influence on material to some extent.

Additional check before in use is required.

$\times$: Cannot be used.

Precautions for the Chemical Resistance Data Table Above

1: This chemical resistance data is based on the chemical resistance of the material, which does not mean the guaranteed value of the product.

2: When you transfer chemicals, make sure to test our products in your actual environment.

3: In case the chemical name is not specified, water solution concentration is saturated and the test temperature is the normal temperature.

4: In case the chemical is the gas, it is not the same as the permeability of the chemical. Please do not transfer chemicals (such as active gas) that are dangerous in case of permeating.

For chemical resistance data of other fluids, please refer to this webpage.

Product Evaluation Data for Ink-Jet Tubing

We can conduct various types of test for our products. Please visit this webpage for our test data. If you cannot find the test data that you would like to have, please consult with us from here.

PFAS-Free Product Series

For water-based and solvent-based inks, we have the following options: E-KYT: KY TUBE (Inner Layer: Olefin), E-BTO: Barrier Tubing (Olefin) (Inner Layer: Polyethylene), and NTU-CL: PFAS-Free Nylon Tubing Clear (Inner Layer: Polyamide).

For UV-Curable inks, we can offer a product, NTU-BK: PFAS-Free Nylon Tubing Black (Inner Layer: Polyamide).

6 Tips to Select the Tube

1: Where is the tube used? Is it for supplying an ink? Is it for waste-ink line? Is it for peristaltic pump?

2: What kind of ink do you transfer? Is it based on water-based inks, solvent-based inks or UV-curable inks?

3: What are the sizes of I.D. and O.D.?

4: What is your requested bending radius for the tube?

5: By when do you need the tube? (If you prefer a made-to-order tubing, you need to take the production lead time into consideration.)

6: What are your requested features (such as flexibility, abrasion resistance, outer layer smoothness, anti-flammability and so on)?

Inner Layer Material Sheet

An inner layer material sheet (L: 100mm x W: 200mm x 2.0mm) is available on request for your ink compatibility test. If you need a material sheet, please contact us. In case you need a different size of the material sheet, please contact us as well.

Frequently Asked Questions

Question 1: It seems that stable ejection of ink from a printing head is not possible, due to the generation of bubbles or the accumulation of air bubble in a tube. What is the cause of this? How can we solve this problem?

Answer 1: The oxygen in the atmosphere (outside the tubing) is taken inside the tubing, leading to the situation that the ink is oxidized and deteriorated. We recommend you to choose E-BTO or E-BTF, barrier tubing products.

Question 2: By changing the viscosity of inks in a tube, the ejection of ink from a printing head is unstable. How can we solve this problem?

Answer 2: This problem comes from the situation that the solvent component of the ink in the tube might volatilize, causing a change in the ink viscosity in the tube and causing the ink to clog. In order to solve this problem, we recommend a E-BTF tubing with solvent-barrier features.

Question 3: When the tubing is in use, the outer layer of the tubing becomes wet, which seems that an ink is coming out. How can we prevent this issue?

Answer 3: It is probable that monomer component of inks is evaporated as time has passed by and penetrated into the outer layer of the tubing. We recommend a E-BTF tubing, as its inner layer has the feature of solvent-barrier.

Question 4: We would like to improve the abrasion resistance of the outer layer, as when the printing machine is in motion, one tubing is shaved with the other tubing, leading to the situation that the tubing is eventually cracked and the ink will leak. How can we solve this problem?

Answer 4: We can customize an ink tubing that will improve the feature of the abrasion resistance of the outer layer.

Question 5: It seems that the matching between an ink tubing and the fittings is not good, leading to the situation that an ink will be leaking from the tubing. Do you have any solutions on this?

Answer 5: We have our original fittings that perfectly fit in well with our tubing series. However, in case you would like to use fittings other than HAKKO original products, please let us know the name of the manufacturer and the part number. We can conduct the matching test and give some advice about whether or not the fittings are usable for our tubing.

20220810.jpg)

.jpg)