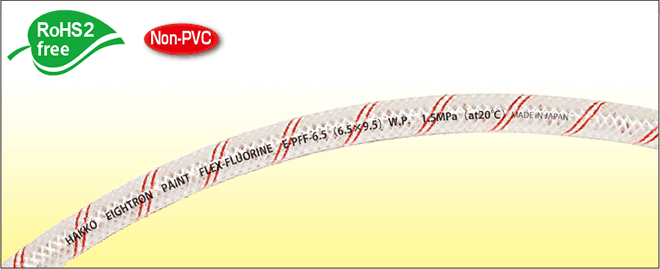

Paint Flex-Fluorine Hose [Model Number: E-PFF]

Solvent Transfer Hose for Solvent-Based and Water-Based Paints | Flexible Paint Hose especially for Water-Based Paints, Organic Solvents; Easier to Wash Out - Recommended for High Viscosity Paints | Long Duration

Fluids

chemicals

chemicals ink

ink paint

paint flux

flux air

air Applications

- For Manual Painting such as Automobiles, Motorcycles and Auto Parts (Solvent-Based and Water-Based Paints)

- For Pipes at Manufacturing Plants of Solvents and Paints

- For Transferring Chemicals

Functions

Solvent Resistance

Non-PVC

Non-Adhesiveness

Chemical Resistance

Pressure-Proof

Transparency

Water Based Paints

Characteristics

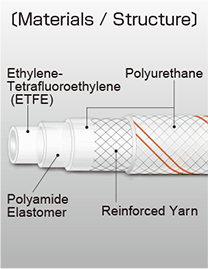

- Water-Based Paints...Since the inner layer is made of ETFE fluorine resin, E-PFF is resistant to most of the paints including water-based paints such as Amine and Alcohol.

- Solvent Resistance...Since the inner layer is made of ETFE fluorine resin, it shows greater levels of solvent resistance against paints, organic solvents, thinner, and so on.

- Easy to Cut...Since we print the cut mark on the hose every meter, it is easy to cut the length you would like to.

- Flexibility...Due to the laminated structure, compared with a single-layer teflon tubing, it shows higher levels of flexibility and kink-resistance.

- Lightweight...Compared with the standard paint hose made of rubber, E-PFF is a lightweight paint hose. As a result, E-PFF leads to the reduction on the burdens of your arms and shoulders.

- Transparency...E-PFF (clear color) enables you to check the fluid very easily.

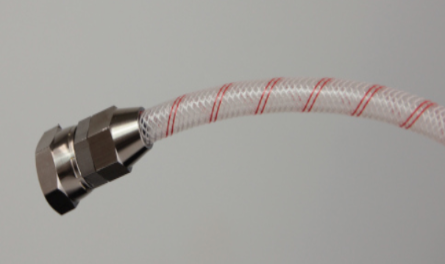

- Original Fittings...By using our original fittings, you can avoid accidents which are caused by incorrect choices of hose and fittings. For more information on our original fittings, please scroll down to the end.

Certificates and Regulations

- RoHS Compliant...E-PFF is compliant with RoHS requirements (Directive: (EU) 2015/863). (RoHS Compliant means that E-PFF does not contain RoHS 10 restricted substances or it does not exceed the upper threshold of RoHS 10 restricted substances.) Certificate is available on request.

- EU REACH and UK REACH...E-PFF is compliant with REACH SVHC 31st list (242 substances). Certificate is available on request.

- Non-Use of UV-328...E-PFF does not contain UV-328. Certificate is available on request.

Packing Images

Product Standard

Hose Only

- Temperature Range : -20 - 60 $^\circ$C (-4$^\circ$F - 140$^\circ$F)

- Color : Clear + Red Line

*Please note that the value of "Minimum Bend Radius" is NOT equal to that of "Flexibility." About "Flexibility," please contact us and request the sample.

Hose with Fittings (Made-to-Order Product)

*If you are interested in E-PFF with fittings, please inform us of your requested part number and quantity on the following form. (We can change the total length into your preferred length.)

Inquiry Form

Leaflet Request

For more information on our Product Standard of E-PFF, please click "Product Leaflet Download" above.

Specification Request

For more technical information (such as Thickness of Each Layer and Precautions in Use) on E-PFF, please click "Product Specification Download" above.

Cautions:

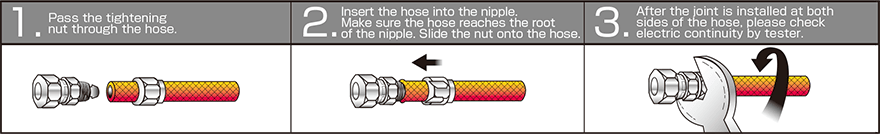

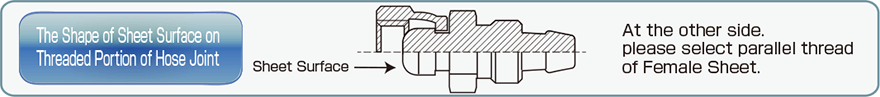

- Due to the laminated structure tubing, please use the joints to seal an inner surface of the hose.

- Please do not use the joints to seal an outer surface of the hose. This may result in the bursting or coming off from the hose.

- When you use our products, please refer to "Precautions for Use." ("The Precautions for Use" of E-PFF is also downloadable here.)

- In terms of chemical resistance, please refer to "Chemical Resistance Data."

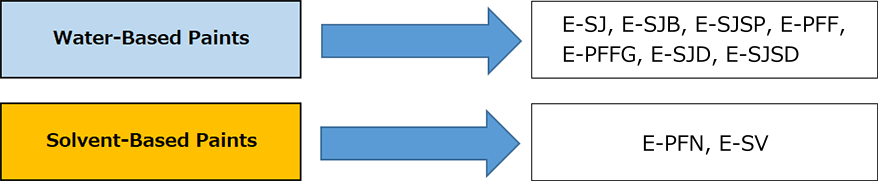

Selection Chart Based on Types of Solvents

Selection Chart for Solvents

Chemical Resistance: = Better = Best

Anti-Static: = Yes $\times$ = No

Vacuum: = Yes $\times$ = No

Technical Information

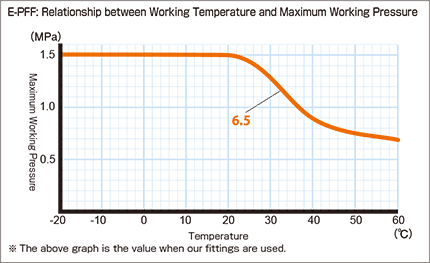

(A) Relationship between Working Temperature and Maximum Working Pressure

(B) Weight Difference between E-PFF and Rubber Paint Hose

This data shows that although E-PFF is much lighter than Rubber Paint Hose A, E-PFF has a larger maximum working pressure value, meaning that E-PFF is a pressure-resistance paint hose.

(C) Paint Hose Series/Data of Soaking into Paint

Test Procedure

Pieces of dumbbell (Inner layer: Nylon Resin and ETFE Fluorine Resin) are soaked into respective types of paint in order to determine the post-soaking tensile strength and calculate its tensile strength in the formula below.

Tensile Strength (%) = (Tensile Strength After Soaking / Tensile Strength Before Soaking) × 100

Soaking Time: 50 Days (1,200 Hours)

Smaller percentage means that the material swells and deteriorates against the chemical. ETFE fluorine resin shows higher paint resistance than Nylon Resin.

This data is measured under the certain circumstances. Thus, depending on the using conditions, environments and duration, this data might not be reliable. The results shown above are NOT guaranteed. Please make sure to check under your working conditions.

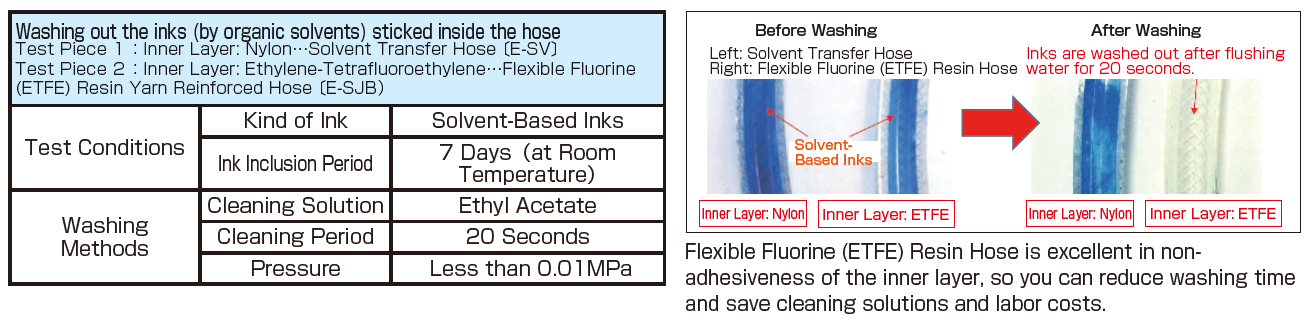

(D) Washability Difference

As you see the images above, a hose with ETFE Fluorine is easier to wash out.

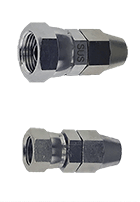

HAKKO Original Fittings for E-PFF

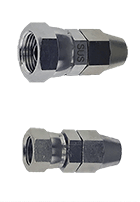

| Product Name | Materials, Characteristics |

| Fittings for Paint-Flex Hose Series [Model Number: E-FS/E-FB]] | E-FS:

- Material: SUS304 (Wetted Part), Brass Nickel Plating (Nut)

- RoHS Compliant

- Thread: G1/4 or G3/8

- SUS Mark around ring means E-FS.

E-FB:

- Material: Brass Nickel Plate

- RoHS Compliant

- Thread: G1/4 or G3/8

|

|

| Fittings for Paint-Flex Hose Series [Model Number: E-FSG/E-FBG]] | E-FSG:

- Material: SUS304 (Wetted Part and Hose Guide), Brass Nickel Plating (Nut)

- RoHS Compliant

- Thread: G1/4 or G3/8

- With Hose Guide: prevent kinking

- SUS Mark around ring means E-FSG.

E-FBG:

- Material: Brass Nickel Plate, SUS304 (Hose Guide)

- RoHS Compliant

- Thread: G1/4 or G3/8

- With Hose Guide: prevent kinking

|

|

How to Install the Fittings and Fittings' Selection Advice